Research Article - African Journal of Food Science and Technology ( 2022) Volume 13, Issue 5

Received: 05-Mar-2022, Manuscript No. AJFST-22-56224; Editor assigned: 07-Mar-2022, Pre QC No. AJFST-22-56224 (PQ); Reviewed: 21-May-2022, QC No. AJFST-22-56224; Revised: 11-May-2022, Manuscript No. AJFST-22-56224 (R); Published: 18-May-2022, DOI: http:/dx.doi.org/10.14303//ajfst.2022.022

Substitution of Cashew kernel milk (CKM) with Skimmed milk (SKM) was used to produce nutritious ice cream with pleasant Cashew flavor and aroma. Five different formulations (10% 20%, 30%, 40% and 50% (v/v) CKM) were developed, while 100% skimmed milk ice cream served as control. The differently formulated ice creams were evaluated for physicochemical parameters like pH,Titratable acidity (TA), Total soluble Solids (TSS) and microbiological stabilities over 3 weeks’ storage period. The proximate and the antioxidant profiles of the ice cream were also determined. Sensory evaluation of the ice cream was done using a 25-member panel who are regular consumers of ice cream. The TA, TSS and pH of all the different ice creams reduced significantly (p<0.05) during storage but less pronounced in samples containing CKM which is concentration -dependent. The proximate compositions showed a range of values of 3.12-3.93% protein, 0.48 -1.07% crude fibre; 0.66 - 2.29 % crude fat and 80.1-82.15% for moisture content. Vitamin C, DPPH and FRAP assay of all the treated ice creams were significantly different (p<0.05) from the control sample and ranged from 4.54 -5.23; 51.97-60.81 and 63.62-70.15% respectively with increase in CKM from 10 % to 40 %. The bacterial and the fungal counts were within standard recommended for ice creams. Sensory evaluation showed significant differences (p<0.05) among the ice cream samples up to 20 % above which the taste becomes unacceptable, colour becomes darker and the overall acceptability becomes lower. Cashew kernel milk can therefore substitute skimmed milk in ice cream production.

Cashew kernel, DPPH, Ice cream, Proximate, Skimmed milk

The awareness of the need to consume healthy foods and foods rich in antioxidants like vitamin C, vitamin E, proteins and dietary fibers is increasing especially for foods that provide nutritional function and new eating experiences for consumers have grown rapidly in recent years Ice cream is one of the most cherished dairy products in the world although most of the commercially available ice cream is generally poor in natural antioxidants like vitamin C, colors and polyphenols. Thus, it is of interest to explore the possibility of improving the nutritional attributes of ice cream using ingredients with health benefit like fruits, vegetables, nuts and pulses, fibers etc. focusing on natural antioxidants, natural colorants, vitamins, low fat and freedom from synthetic additives in the light of consumer expectations. Cashew is a tropical tree crop containing pseudo apple and sickle shaped nut and has many appealing consumer traits including flavor, color and nutritional content, especially vitamin C (Emelike et al., 2019).

Cashew (Anacardium occidentale L.) is an example of tropical tree crop that belongs to the Anacardiaceae family which grows extensively in India, Brazil, East Africa and Vietnam. The tree grows well on different soil types under different climatic conditions. Cashew kernel has seldom been widely utilized in other food applications as pea nuts (Aroyeun, 2009) in Nigeria despite the tremendous rise in its yearly production. In the last few years, the production of cashew nuts/kernels in Nigeria has increased from 30,000 tons in 1990 to 176,000 tons in 2000. About 60% of cashew kernels are consumed in form of snacks while a significantly low volume has been used in the production of differently formulated cashew kernel-based snacks. The remaining unutilized portions have been regarded as wastes due to lack of storage facilities. Cashew kernel is a rich source of fat (47.1%), ash (4.7%), fibre (1.2%) and protein (19.8%) (Emelike et al., 2015), (Aremu et al., 2006)

The current trends in the surplus harvest of cashew have necessitated the need to add values to the kernels in order to optimize income associated with cashew farming and trade. Cashew sold ordinarily in raw state does not attract premium in the international market due to lack of good grading system in Nigeria as a result of poor infrastructural facilities to obtain a whole cashew kernel that will attract premium in the international market. Many previously published research reports have emphasized development of different products from the cashew kernels with significant sensory acceptability. Developed nutritional biscuits from cashew kernel meal also developed cashew kernel based Kulikuli and Dankwa, commonly relished snacks in the southwestern and the Northern Nigeria while produced special kulikuli in the eastern part of Nigeria. Developed cashew kernel milk, an example of milk analogue similar to tigernut milk, peanut milk and hazelnut milk respectively. Consumption of cashew-based products has the potential to offer health benefits including alleviating constipation and improving stool transit time and/or bulking (Emelike et al., 2015), because of constituents such as vitamin C, polyphenols, carotenoids and fiber polysaccharides. Dietary intake of vitamin C is essential for humans because human’s body system cannot synthesize vitamin C. A single cashew apple has been considered to contain twice the vitamin C contents in citrus fruits as it contains the minimum daily requirement for vitamin C suggesting that cashew fruitderived products could be an excellent source of this essential vitamin (Ebere et al., 2015).

Ice cream is made from milk ingredients (milk fat and milk solids-not fat), sugar, water, and other optional ingredients such as flavorings, colors, stabilizers, and emulsifiers. The ice cream flavor and color are normally generated through adding a small amount (i.e. approximately 0.3% ice cream mix). Based on the nutritional profiles of cashew kernel milk, its antioxidant benefits and health values as reported in other food products, this study was developed to substitute skimmed milk powder in the production of ice cream with the aim of establishing the effect of its partial supplementation on the antioxidant profiles and nutritional contents. Microbial stability and its sensory qualities in comparison with the control without CKM is also reported (Turgut et al., 2009).

Sample Collection

Nuts from cashew trees were obtained from production areas located at the Cocoa Research Institute of Nigeria, Ibadan Experimental Station, Oyo state, Nigeria. Cashew nuts were processed to obtain the kernels which include steps like: i) Manual harvesting and apple (peduncle) detaching; ii) Manual cleaning to eliminate strange materials such as leaves, stones, sand and pieces of cashew apples; iii) Sun drying for 2-3 days to reduce the moisture to 7-8%, Heating/ steaming for 20 min, vi) Cooling to room temperature at 28°C for 10-12 h to bring the steamed nut to equilibrium with the atmospheric conditions; vii) Shelling to remove kernels with the help of a hand cum pedal operated cutter (hand built); viii) Drying of cashew kernels with hot air at 65-70°C for 6-8 h, until 5-8% moisture content; ix) Manual peeling with knives to remove the brown testa; and x) Packing in aluminum bags for use.

Production of cashew kernel milk

Extraction of milk from cashew kernel was carried out as described by (Adedokun et al., 2014) with little modifications. Roasted Cashew kernel was divided into three portions of 450g each and then soaked in 250ml of portable water for 6 hr. After soaking, the water was drained and each portion of the soaked kernel blended (using Philips HR2000 blender) into slurry at the ratio of kernel to water of 1:6 (w/v). The slurry was filtered using a clean piece of white triplefolded muslin cloth to separate the milk. The supernatant was further extracted with water and the milk was pooled together and then concentrated into ¼ of the initial volume. The milk was boiled until frothing stopped. The extracted milk was later reserved in the fridge for further use.

Cashew Kernel milk Skimmed milk Ice Cream Production

Different percentage levels of cashew kernel milk were used to replace skimmed milk at 10, 20, 30, 40 and 50% CKM/ SKM ratio respectively. The ice cream mix was prepared in 250 g batches. All the required ingredients such as Milk solid non-fat (MSNF), milk fat (MF), milk blends CKM/SKM, sugar, stabilizer and emulsifier blend (CREMODAN) and water were thoroughly mixed, and the mix was pasteurized at 800 C for 30 s and homogenized in a two-stage process, at 13.8 MPa and 3.6MPa for 5 min using ULTRA -TURRAX IKA-T25 digital (Werke Staufen, Germany). The ice cream mix was then rapidly cooled to room temperature and aged at 4oC overnight. No flavor was added to the ice cream mix prior to freezing to avoid any unrelated flavor impact to the ice cream. The ice cream mix was whipped by using an ice cream maker (Kenwood, Model: IM 280, UK) at a constant speed for about 20 min. The whipped ice cream mix was filled into a plastic container and stored in the freezer frozen at -20°C.

Storage test

The ice cream was stored in the freezer for 3 weeks and the physicochemical and the microbiological analyses were carried out on weekly basis.

Physicochemical Analyses of cashew kernel milk / skimmed milk formulated ice cream

The ice cream mix was subjected to physicochemical analyses such as, pH, Titratable acidity (TA) and the Total soluble solids (TSS). Measurements were done in triplicates.

pH

The pH meter was previously calibrated with pH 7.0 and 4.0 standard buffers before the commencement of the analyses. Ice cream samples were first melted under room temperature (28°C). The pH of the melted ice cream samples was measured using a pH meter model: 3505 pH meter, Jenway, UK.

Titratable acidity

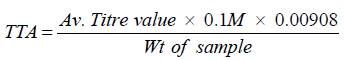

The percent titratable acidity was determined as described by the mean of TA was obtained from triplicate determination and calculated as follows:

The TA were recorded a % lactic acid (Fabro et al., 2006)

Total Soluble solids (TSS in OBrix)

The TSS (°Brix)) involves the determination of Total Sugar Level: The total sugar level (°Brix) of each ice cream sample was carried out using refractometric method (Soluble solids) using hand Refract meter (Atago Brix 0-32% Model TM 1600, Gibertini, Italy). The Refract meter was cleaned and standardized using distilled water at 20°C to 1.333 Refractive Index. Small drop of ice cream sample was put into the Refract meter to determine the refractive index of the milk at 20°C.

Determination of Vitamin C

Vitamin C determination was done according to the method described by (Awonorin & Udeozor, 2014).

Determination of Antioxidant Activities

DPPH Assay:

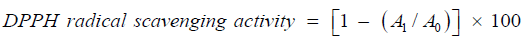

DPPH (2,2-Diphenyl-1-picrylhydrazyl) radical inhibition values of samples were assessed following the modified method of (Chaikham et al., 2012). The samples (5 g) were well-mixed with 20 mL of 100% methanol for 15 min before centrifuging at 3,000 rpm for 10 min, and subsequently filtered through the Whatman No. 4 filter paper. The filtrates (1.6 mL) were then mixed with 0.4 mL of 1.5 μM DPPH in methanol. After 30 min of reaction, the absorbance values of blue-complex solutions were measured using a spectrophotometer (Perkin Elmer UV WINLAB; Perkin Elmer, Waltham, MA) at λmax of 517 nm. Percentage inhibition of DPPH radical was calculated following the formula:

where, A0 = absorbance of control (methanol) and A1 = absorbance of the sample.

FRAP Assay:

This was determined according to the method of (Benzie et al., 1996). 3 mL of FRAP (Ferric reducing antioxidant power) reagent (10:1:1 of 300 mm pH 3.6 sodium acetate buffer, 10 mm 2, 4, 6-tripyridyls-triazine solution, and 20 mm FeCl3.6H2O solution) was poured into 10 mL of the filtrate (as prepared in above section), mixed and incubated at 37°C for 30 min. The absorbance of the mixture was measured at λmax 593 nm and the FRAP value was expressed as mm FeSO4 /100 g sample.

Microbiological Analyses:

The ice cream samples were evaluated for microbiological parameters using standard methods. 5 g of melted ice cream samples and the control were aseptically homogenized in 10 ml of sterile ringer solution; 3 ml of the mixture were plated in the different culture media to obtain the number of CFU/g of product. Moreover, decimal dilutions were plated in the same culture media.

The microbial groups investigated were total microbial counts of mesophilic aerobic microorganisms, determined in Plate count Agar (PCA) medium (Oxoid) and incubated at 30°C for 48hours under aerobic conditions; total coliforms in violet red bile Agar (VRBA) (Oxoid, 37°C), 24h under aerobic conditions. Lactic acid bacteria was determined using De Manns Rogosa Agar (MRS); Staphylococci using mannitol salt agar (MSA); Moulds were enumerated using potato dextrose agar (PDA) medium (oxoid). The same microbial groups were evaluated weekly till the end of the storage period.

Sensory Evaluation:

The sensory evaluation of the ice cream samples was conducted using an acceptance test. Each analysis was performed by 25 untrained panelists between 18- and 40-years old members of staff of the Cocoa Research Institute of Nigeria and students’ members on industrial training from different polytechnics and universities out of which 13 were male while 12 were female. The ice cream samples were provided in 50 mL cups, with approximately 20 g of each sample coded with a three-digit random letters. Sensory attributes of samples were evaluated using a 9-point hedonic scale with 9 indicating-extremely like, 5 -neither like nor dislike and 1= extremely dislike respectively. The sensory attributes of Taste color, flavor, and overall acceptability were evaluated. Participants were informed of every detail of the scope of the study before commencement of the evaluation.

Statistical Analysis:

All data were generated from the means of triplicate determinations with standard deviations (S.D). Analysis of variance (ANOVA) was carried out using SPSS version 23 for Windows (SPSS Inc., Chicago, IL, USA), and the determination of significant differences among treatment means was conducted under Duncan’s multiple range tests (P ≤ 0.05).

The physicochemical changes in the different ice creams were shown in (Table 1). A significant variation in the pH of the ice creams were observed.

| Weeks | Sample | pH | %TA | OBrix | SG |

|---|---|---|---|---|---|

| 1 | 10%A | 7 | - | 3 | 1.01 |

| 20%B | 7 | - | 6 | 1.025 | |

| 30%C | 7.1 | - | 9 | 1.035 | |

| 40%D | 7.1 | 0.268 | 11 | 1.041 | |

| 50%E | 7 | 0.536 | 12.5 | 1.05 | |

| 100% milk F | 6.7 | 0.268 | 21 | 1.088 | |

| 100% Cashew G | 5.2 | 0.804 | 21.4 | 1.09 | |

| 2 | 10%A | 6.7 | - | 2.4 | 1.008 |

| 20%B | 6.9 | - | 6 | 1.025 | |

| 30%C | 6.9 | - | 7.8 | 1.032 | |

| 40%D | 6.3 | - | 9 | 1.035 | |

| 50%E | 6.9 | 0.268 | 11.6 | 1.045 | |

| 100% milk F | 6.7 | 0.268 | 18.8 | 1.076 | |

| 100% Cashew G | 4.3 | 0.536 | 19 | 1.079 | |

| 3 | 10%A | 5.7 | - | 2.4 | 1.009 |

| 20%B | 4.2 | - | 4 | 1.015 | |

| 30%C | 5.9 | - | 7 | 1.028 | |

| 40%D | 4.4 | - | 7.1 | 1.029 | |

| 50%E | 5.5 | 0.268 | 7.2 | 1.042 | |

| 100% milk F | 6.4 | 0.268 | 16.6 | 1.075 | |

| 100% Cashew G | 4.1 | 0.266 | 17 | 1.076 |

Results from chemical assessments of all ice cream demonstrated similar trends of reduction in pH and increase in titratable acidity following 21 day frozen storage. The initial pH of samples ranged from 5.20 to 7.0, and subsequently decreased to pH range of 4.1 to 5.7. Comparing the skimmed milk-based ice cream samples and cashew kernel-based ice creams, the pH reduction was gradual at the beginning of storage and sample A had a pH of 7.0 at the 1st day and subsequently reached pH 5 at the end of the 21st day of storage. The titratable acidity increased with storage period and increases with increased concentrations of the CKM with a corresponding decrease in pH. The cashew kernel milk showed a lower pH values than the SKM while the cashew kernel milk contained a higher titratable acidity values when compared to the ice cream containing SKM. The presence of different acids in cashew including anacardic acids might be responsible for the impact of the acids on the pH of the CKM based ice cream with increasing levels of CKM in the mix. The titratable acidities found in this study were quite lower than the ones reported by the ice cream containing black thorn fruit perhaps having more organic acid than cashew.

Treatable acidity of the three ice cream samples which ranged from 0.19% to 0.20% shows no significant difference (p > 0.05). The results were within the level reported. Who mentioned that the ice cream mix containing 11.7% MSNF would have a normal acidity range of 0.19-0.22%. This situation was probably due to some organic acids that are produced during the storage. Apart from the organic acid production during the storage though very insignificant in quantity, other reasons associated with the changes in the acidities might be connected to the organic acids present in the cashew kernel. Similar results were reported in the work of where black thorn fruits were used in the formulation of functional ice cream. The effects of CKM supplementation in the ice creams were evident from the values obtained for the TSS. It was observed that with an increase of CKM, the sugar contents of the ice cream increased significantly (p < 0.05) as measured by the Brix. The sugar present in milk is lactose and it is not as sweet as sucrose and the sugar in cashew was a sucrose sugar which obviously might have caused the higher Brix in the ice cream in which cashew milk was supplemented than the 100% SKM-based ice cream. The total soluble solids as measured by the Brix increases steadily and reached the maximum level at the 50% addition. The sweetness of CKM based ice cream was higher than the SKM. The values of TSS recorded in this study was lower than the report who recorded a range of values of 15.1%-15.38% for the TSS in the ice cream in which Brocolli was substituted at 10% to 30%. This difference might be due to the differences in the supplementing material and in this case the possibility of difference in sweetness between CKM and broccoli might have contributed. The increased quantity of CKM resulted in a stable ice cream and a reduced biochemical change that may result in deterioration in storage. Activities of microorganisms resulted in sugar reduction and increase in acidities during storage which was not the case in this present study.

The range of lipids in the ice cream studied was 2.07 to 2.66%. The Ice cream with cashew kernel milk had lower lipid content, differing significantly from control ice cream containing 2.69% fat (Table 2). As the replacement level of CKM increases from 10%, the %lipid decreases steadily and reached the lowest level at the 50% replacement with percentage lipid contents of 2.07%. The average reduction in fat content of ice cream with added cashew kernel milk was significant when compared to the control ice cream with 2.69% lipid (p <0/05). This result was comparable with the ones published by (Prindiville et al., 2000). Who achieved a reduction of 65-68% in fat content of chocolate ice cream by adding several fat replacers based on proteins?. Similar result was also achieved who reported a reduction in percentage fat contents of ice cream produced by using orange by products as fat replacer. This study which highlighted the use of cashew kernel milk as a fat replacer in ice cream production as a result of the fat reduction properties is demonstrated in this present work. The recommended % standard fat content of ice cream was 12% according to the work of (Choo et al., 2010). (Hui et al., 2004) also pointed out that ice cream with fat content of 12- 15% usually has 38-40% of total solid content and 60-90% of overrun meaning that the total solids of the ice cream reported in this present work and the overrun may be lesser and constitute a kind of functional foods with nutritional benefits. This slight difference probably can be explained by different fat sources which were in the ice cream mix. The moisture contents recorded in the ice cream analyzed in this study varied significantly and increased with a rise in CKM in the blends.

| Sample | Crude protein | Crude fat | Crude Fiber | Total Ash | Moisture Content | Dry Matter | CHO |

|---|---|---|---|---|---|---|---|

| A | 3.12 | 2.66 | 0.08 | 3.87 | 80.17 | 18.31 | 13.1 |

| B | 3.14 | 2.49 | 0.21 | 3.89 | 81.89 | 18.61 | 11.0 |

| C | 3.60 | 2.43 | 0.43 | 3.95 | 80.06 | 80.06 | 12.43 |

| D | 3.93 | 2.29 | 0.36 | 3.97 | 80.97 | 80.97 | 11.38 |

| E | 2.18 | 2.07 | 0.14 | 3.69 | 81.31 | 81.31 | 13.61 |

| F | 3.48 | 2.69 | 0.25 | 3.12 | 81.39 | 81.39 | 13.17 |

| G | 3.79 | 2.42 | 0.39 | 3.94 | 82.15 | 82.15 | 10.31 |

The range of values for the MC was 80.06 to 82.15%. These values were not in conformity with the work of who reported a range between 63.01 to 69.96%. The difference might be due to variations in the recipe formulations. The changes in % protein contents in the different ice creams were evident according to Protein contents increased significantly with an increase in CKM in the mix and ranged between 3.12% at the 10% level of CKM inclusion, rose to a maximum of 3.93% and later decreased at the 50% level of inclusion. This result showed a higher % protein in cashew kernel milk ice cream than the corresponding control skimmed milk ice cream. The percent protein reported was lower than the values obtained in this study. The range of values obtained in ice cream formulated with orange by products was between 2.48% and 2.87%. The difference in the percentage protein contents reported by might be due to the fact that the raw material used in our study was a proteins kernel and contained more protein than citrus by product. Typically, the protein content of ice cream is approximately 4% and the 0% protein content obtained in the ice cream recorded in this study was within the level of protein for ice cream. Besides that, the obtained fat content is 11% for all the samples, which is slightly lower than the actual fat content, 12%. These may be explained by the modified Gerber method which had eliminated the centrifugation step due to limitation of equipment. The supplementation of normal skimmed milk with cashew kernel milk in the production of ice cream as evidenced in this study has indicated the nutritional and nutraceutical effects of the CKM and hence making the ice cream to be considered as an example of functional food.

Antioxidant Activity of Ice Cream Samples during Frozen Storage

According to (Table 3). Vitamin C increased steadily with increase in cashew kernel in the blends. This is due to the fact that vitamin C has high bioavailability. It is an essential water-soluble antioxidant in cells and an efficient scavenger of reactive oxygen species. Foods rich in vitamin C include fruits such as berries, papaya, kiwi and citrus fruits, vegetables such as Brussels sprouts, cauliflower, cabbage and sweet pepper and herbs/spices such as parsley, sorrel and chives. Animal tissues also contain vitamin C but in lower amounts. Average vitamin C intake from food ranges from 69 to 130 mg day-1 in men, from 65 to 138 mg day−1 in women and from 11 2 to 65 mg day-1 in children. This analysis is also important

| Samples | Vitamin C (%) | DPPH (%) | FRAP (Mm FeSO4/100 g) |

|---|---|---|---|

| A | 4.56 | 52.82 | 63.69 |

| B | 4.89 | 56.60 | 66.71 |

| C | 4.90 | 57.96 | 69.49 |

| D | 5.02 | 60.81 | 70.15 |

| E | 3.97 | 51.97 | 63.62 |

| F | 4.54 | 53.05 | 65.79 |

| G | 5.23 | 63.24 | 75.11 |

DPPH inhibition and vitamin C values were at maximum in the 40% supplementation level and in the order 10% <20% <30% <40% respectively. The cashew milk contained higher antioxidant contents than the control skimmed milk while significant differences in FRAP assay followed the same concentration dependent trend.

The microbiological profiles of the ice cream shown in (Table 4). Reflected variations in the bacterial counts, fungal counts, the staphylococcus, Ecoli, yeasts, moulds and the lactic acid bacteria counts. The yeast count reduces significantly with increased level of cashew kernel milk in the formulation. The range of values recorded in all the ice cream samples were within recommended levels. The yeast count ranged between < 100 to 2.32 × 105 CFU/g. The presence of staphylococcus species was not detected in all the samples analyzed. The lactic acid bacteria were detected up to the second week of storage and later no growth was recorded. The reduction in LAB was observed with the increased level of CKM in the blends. The total viable counts also reduced significantly as the CKM increased in the formulations while there were no records of coliform in the ice cream samples. This study established the safety of the produced ice creams as coliform counts and the staphylococci counts were indicative of contamination during handling or storage. The cold storage used in this study was able to stabilize the ice cream samples from the beginning of storage till the 3rd week of storage. There is also an indication that pasteurization was adequate. Mold growth was not recorded in this study.

| Samples | Flavour | Taste | Colour | Texture | Overall acceptability |

|---|---|---|---|---|---|

| A | 7.10 ± 0.88ab | 7.30 ± 1.06ab | 7.00 ± 2.05a | 8.46 ± 0.02a | 7.00 ± 1.05ab |

| B | 7.90 ± 1.60a | 8.20 ± 1.03a | 7.50 ± 1.58a | 8.2 ± 0.01a | 80 ± 0.79a |

| C | 6.80 ± 2.30ab | 7.10 ± 1.52ab | 7.00 ± 0 .82a | 7.36 ± 0.03b | 6.60 ± 2.22ab |

| D | 6.40 ± 1.84ab | 6.70 ± 1.42ab | 7.40 ± 0.84a | 6.62 ± 0.01c | 6.80 ± 1.23ab |

| E | 6.80 ± 1.75ab | 6.70 ± 1.70ab | 6.60 ± 1.07a | 6.11 ± 0.02c | 7.10 ± 1.73ab |

| F | 5.70 ± 2.06b | 5.90 ± 2.23b | 6.70 ±1.89a | 5.55 ± 0.03d | 6.60 ± 2.22ab |

| G | 6.00 ± 2.75ab | 6.10 ± 2.02b | 6.50 ± 1.51a | 5.34 ± 0.01d | 6.40 ± 1.84b |

Moulds were unable to grow under freezing temperature in a well pasteurized sample. Salmonella are examples of organisms that have been reported in the typhoid diseases and care was taken to avoid contaminations by handlers or other sources including surfaces and utensils used during the ice cream processing. The inclusion of CKM in ice cream as evident in this study is the first report and the novelty of this work can be validated from the values of vitamin C, DPPH and FRAP assay of the ice cream samples in which CKM have been incorporated. The increase in protein over the control is also an indication that there is no loss in % protein but rather there was a rise in % protein after the CKM incorporation. The reduction in % carbohydrate and % fat contents is also desirable effect on the health beneficial effects of the newly developed cashew kernel milk based ice cream.

The results of the sensory evaluation of cashew kernel based ice cream. Significant differences were observed in all the evaluated sensory attributes and the control sample in terms of flavor with sample B being the highest rated than all the other samples of ice cream. Although there were no significant differences in samples A, C, D, E and G in flavor, it was observed that the flavor of cashew milk was not strong enough to over shadow the normal skimmed milk based ice cream (Kaneko et al., 2018). Reported that dairy product has a mild flavour which is easily affected by stronger flavors of other compounds. Sample F was the lowest among all the samples in flavour. The flavour of ice cream in this study decreased significantly when the skimmed milk was replaced by cashew kernel milk at C, D, and E respectively. The flavour appreciation of the panelists was concentration-dependent of the cashew kernel milk. Additionally, the taste attributes of the ice cream were found to differ significantly showing a decreasing trend with increase in cashew kernel milk in the blend. Skimmed milk is rich in lactose sugar which is low in sweetness and a further increase in substitution with cashew kernel milk as evidenced in this study resulted in a decrease in sweetness of the ice cream product. This report is in consonance with the reports. Who reported the reduction in sweetness in dairy product supplemented with soya milk. Only sample B had a high rate in taste when compared to other samples which reduced as the Cashew kernel milk increased in the blends.

The colour attributes of the ice cream also differed significantly (p < 0.05) among the samples with sample B having the highest color rating than all the other samples. Although the scores for the sample B was highest in all the samples, there was no significant difference between sample B and other ice cream samples in terms of colour attributes meaning that increasing cashew kernel milk substitution might not affect colour of the ice cream. The texture of the ice cream also showed a decreasing trend in all the ice cream significantly (p < 0.05) with increased cashew kernel milk substitution. The alteration of the textural properties might be due to the lack of casein in cashew milk to increase the texture. Lack of casein in milk analogue such as experienced in this study might have reduced gelling potential of the ice cream. This conforms with the reports of (Kailasapathy et al., 2006), who reported that increasing the addition of soya milk resulted in a reduced texture attributes of dairy product at 40 and 60% level of supplementation. The overall acceptable level of cashew kernel milk supplementation in the present study was 20% according to the panelists and above this level, the taste become poor and un acceptable.

The addition of CKM significantly affected the physical, chemical, color, sensory and antioxidant characteristics of ice cream. The increment of CKM level caused increased acidity, vitamin C and antioxidant values compared with the control Ice cream. The antioxidant and radical-scavenging activities of CKM based ice cream can be attributed to its content of phenolic and flavonoid compounds. CKM can be used as an easily accessible source of natural antioxidants and as a potential food supplement. Moreover, CKM could be used in ice cream production as a source of pleasant taste, texture and flavor. Therefore, CKM, may be used as a suitable source of natural additives in ice cream production to enhance flavor, nutritional value and natural color. The percentage level of addition in which the physicochemical, microbiological and the antioxidants levels of the ice cream were acceptable was 20% (CKM: SKM).

Adedokun II, Okorie SU, Batu B (2014). Evaluation of proximate, fibre qualities and consumer acceptability of bambaranut-tigernut-coconut milk beverage blends. Inter J of Nutr and Food Sci. 3: 430-37.

Indexed at, Google Scholar, Cross Ref

Aremu MO, Olonisakin A, Bako DA et al. (2006). Compositional studies and physico-chemical characteristics of cashew nut (Anacardium occidentale) flour. Pak J Nutr. 5: 328-333.

Aroyeun SO (2009). Utilization of cashew kernel meals in the nutritional enrichment of biscuit. Afr J Food Sci. 3: 316-319.

Indexed at, Google Scholar, Cross Ref

Awonorin SO, Udeozor LO (2014). Chemical Properties of Tiger nut-soy milk extract. IOSR J Environ Sci Toxicol Food Technol. 8:87-98.

Indexed at, Google Scholar, Cross Ref

Benzie IFF, Strain JJ (1996). The Ferric Reducing Ability of Plasma (FRAP) as a Measure of Antioxidant Power: The FRAP Assay. Anal Biochem. 239: 70-76.

Indexed at, Google Scholar, Cross Ref

Chaikham P, Apichartsrangkoon A (2012). Comparison of dynamic viscoelastic and physicochemical properties of pressurised and pasteurised longan juices with xanthan addition. Food Chem.134: 2194-2200.

Indexed at, Google Scholar, Cross Ref

Choo SY, Leong SK, Henna FS (2010). Physicochemical and sensory properties of ice-cream formulated with virgin coconut oil. Food Sci and Technol Intern. 16: 531-541.

Indexed at, Google Scholar, Cross Ref

Ebere CO, Emelike NJT, Kiin-Kabari DB (2015). Physico-chemical and sensory properties of cookies prepared from wheat flour and cashew-apple residue as a source of fibre. Asian J Agric Food Sci. 3: 213-218.

Indexed at, Google Scholar, Cross Ref

Emelike NJT, Akusu OM (2019). Physicochemical, mineral and sensory characteristics of cashew nut milk. Inter J Food Sci Biotech 4: 1-6.

Indexed at, Google Scholar, Cross Ref

Emelike NJT, Ebere CO (2015). Effect of packaging materials, storage time and temperature on the colour and sensory characteristics of cashew (Anacardium occidentale L.) apple juice. J Food and Nutr Res. 3: 410-414.

Indexed at, Google Scholar, Cross Ref

Emelike NJT, Ebere CO (2016). Effect of treatments on the tannin content and quality assessment of cashew apple juice and the kernel. Eur J Food Sci Technol. 4: 25-36.

Fabro MA, Milanesio HV, Robert LM, Speranza JL, Murphy M (2006). Technical Note: Determination of acidity in whole raw milk: comparison of results obtained by two different analytical methods. J Dairy Sci. 89: 859-861.

Indexed at, Google Scholar, Cross Ref

Hui YH, Legaretta IG, Cornillon P, Lim MH, Murrell KD et al., (2004). Handbook of Frozen Foods. New York: CRC Press, 499-519.

Indexed at, Google Scholar, Cross Ref

Kailasapathy K, Chin J (2006). Survival of free and encapsulated probiotic bacretia and their effect on the sensory properties of yoghurt. LWT Food sci Tech. 39: 1221-1227.

Indexed at, Google Scholar, Cross Ref

Kaneko D, Toet A, Brouwer A, et al., (2018). Methods for Evaluating Emotions Evoked by Food Experiences: A Literature Review. Front Psycho.9: 911.

Indexed at, Google Scholar, Cross Ref

Prindiville EA, Marshall RT, Heymann H (2000). Effect of milk fat, cocoa butter, and whey protein fat replacers on the sensory properties of low fat and nonfat chocolate ice cream. J Dairy Sci. 83: 2216-2223.

Indexed at, Google Scholar, Cross Ref

Turgut T, Cakmakci S (2009). Investigation of the possible use of probiotics in ice cream manufacture. Int J Dairy Technol. 62: 444-51.