Full Length Research Article - African Journal of Food Science and Technology ( 2023) Volume 14, Issue 1

Received: 12-Dec-2022, Manuscript No. AJFST-22-83167; Editor assigned: 15-Dec-2022, Pre QC No. AJFST-22-83167; Reviewed: 29-Dec-2022, QC No. AJFST-22-83167; Revised: 03-Jan-2023, Manuscript No. AJFST-22-83167; Published: 12-Jan-2023, DOI: 10.14303//ajfst.2023.003

Postharvest loss of fruit and vegetables is significant in developing countries and the major problem is lack of appropriate storage system. Evaporative cooling is the cheapest and effective way of cooling storage structure compared with commercial cold storage, which is expensive and inapplicable in rural areas without electricity. Two direct evaporative coolers Zero energy cooling chamber (ZECC) and pot in pot refrigerator (PIP) were constructed and evaluated for their capacity in reducing environmental temperature and extending postharvest life of tomato fruit. The shelf life of tomato was evaluated through weight loss and temperature measurement. Zero energy cooling chamber was effective in reducing environmental temperature from 32 oC to 10 oC and extended the shelf life of ripe tomato fruit from 6 days to 15 days. Pot in pot refrigerator was found cheaper and more effective by reducing environmental temperature from 35 oC to 8 oC and extending ripe tomato from 6 days to 15 days. More effective evaporation can be achieved through optimizing the design of evaporative cooler and both evaporative colors are more effective when atmospheric temperature rises.

Evaporative cooling, Pot in pot refrigerator, Temperature, Tomato.

Evaporative cooling is the green technology for cooling air by evaporation of water. The main advantage of evaporative cooling technologies is it do not require mechanical or electrical energy to work and are therefore appropriate for smallholder farmers in rural areas without electricity (Basediya et al., 2013). Evaporative cooling is a physical phenomenon in which evaporation of a liquid, typically into surrounding air, cools an object or a liquid in contact with it. Evaporative cooling is an efficient and economical means for reducing temperature and increasing the relative humidity of an enclosure, and has been widely tried for enhancing the shelf life of horticultural produce (Basediya et al., 2013). Evaporative cooling can be classified as direct and indirect evaporative cooling. Direct evaporative cooling works on the principle of sensible heat conversion to latent heat when water evaporates from wetted medium and gives the wet bulb temperature (Ambuko et al., 2017). Direct evaporative coolers tested in this research are Zero energy cooling chamber and pot in pot refrigerators. Zero energy cooling chambers is made with double walled bricks with openings in between the walls where it is filled with sand and water is sprayed. While water is evaporative form wet sand sensible heat is converted into latent heat to give wet bulb temperature that cools the storage system. Conductive and convective heat transfer occurs in the system. Through conductive heat transfer heat is transferred from sand to inside wall and through convective heat transfer inside storage space is cooled (Hasan, 2012).

Zero energy cooling chambers can be used as small or large scale storage systems. Pot in pot cooler/refrigerator is the most effective direct cooling technology first investigated in Nigeria. It is art of pottery made from clay soil by mixing, molding and burning in the fire. The pot - in - pot design which is popularly used consists of two clay pots (Pandey & Pesala, 2016). The first pot is a large pot inside which the second smaller pot can be placed (Olosunde & Olurin, 2009). A produce to be preserved is placed inside the smaller inner pot. The space in between the two pots is filled with sand and the sand acts as a medium to retain water required for evaporative cooling.

Fruits and vegetables are perishable due to high moisture content and high respiration rate. Shelf life of fruits and vegetables is highly influenced by storage temperature, gas composition and relative humidity (Arah et al., 2016). Low temperature, low oxygen and high relative humidity storage conditions are favorable for most fruits and vegetables (Pan et al., 2019). Temperature is one of the major factors that can cause physiological damage to fruit and vegetables resulting in shorter storage life and reduced quality. Temperature-mediated changes in plant respiration are important component of the biosphere’s response to global climate change. Almost all biochemical reactions are catalyzed by enzymes. Temperature is the most significant factors in maintaining quality and extending the shelf life of fruit and vegetables, and low temperature storage is an effective way delay ripening after harvest (Pan et al., 2019).

Design of evaporative coolers

Zero energy cooling chamber structure was consisted of 400 bricks, which had a rectangular, double walled chamber carrying heat insulating detachable roof and constructed nearby source of water supply. The dimensions of the outer wall was190cm × 130cm × 45 cm length, width and height respectively. The gap covers 7.5 cm between the double wall surfaces, which was completely filled with wet river sand.

Two pot designs with bigger and smaller size were designed and using clay soil specific pot design was developed. The smaller pot was inserted in the bigger pot and the space in between was filled with sandy soil and water was sprayed on the soil.

Tomato sample selection

A tomato fruit of uniform size fully sound was selected purposely from market. A surface dust was cleaned by using water. The tomato was stored in the pot-in-pot storage, zero energy cooling chamber and regular air storage conditions.

Temperature measurement

By using thermometer the temperature variation was recorded inside zero energy cooling chamber and regular atmospheric air. Also temperature was measured inside pot-in-pot refrigeration and regular atmospheric air. Temperature measurement in both evaporators was done separately in different time interval.

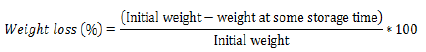

Physiological weight loss

The tomato sample weight loss was determined by weighing tomatoes in three days interval for fifteen days. For the determination of weight loss during regular air and evaporative cooler storage, tomato fruits marked at the start of experiment from each treatment and kept separate for periodic weighing using an electronic balance. The difference in weight loss was expressed as a percentage of weight loss from the initial fruit weight.

Data analysis

The data collected from laboratory analysis was analyzed by comparing the two treatments analytically using data analysis tool pack SAS software which compare the mean of two treatments having equal mean, to determine whether difference are there in tomato attributes and significantly test (p<0.05) between and within the treatments was conducted.

Reducing environmental temperature via Zero energy cooling chamber (ZECC) technology

As shown in figure 1 the construction of ZECC was successfully performed with in a small plot of land. The fundamental performance ZECC was first investigated from the daily environmental temperature variations. An increase in outside temperature leads to decreased the inside temperature of the ZECC. The maximum values of the outside and inside ZECC temperatures were 32 and 10°C, respectively. Conversely, the minimum values of the inside and outside ZECC temperatures were 19°C and 15°C, respectively. (Length, 2012) also explained that environmental factors such as temperature and relative humidity influenced the rate of respiration. Accordingly, the greater the storage temperature is, the higher would be the heat of respiration leading to lower storage life expectancy. Average inside temperatures of 14.3oc were recorded in the ZECC under regularly watering with shading from the 15 consecutive days as shown in figure 2.

Evaluating ZECC in extending the shelf life of tomato

The evaluation of effectiveness was determined by firstly observed the temperature difference of the two storage temperatures. The temperature in the case reduced dramatically at reasonable level. This shows that strong relation with the shelf life of products and temperature, because of temperature can facilitate the metabolism of produces and lead to accelerate their deterioration rate.

According to figure 3, the weight loss of fruit and vegetable were dramatically increased during storage. red tomatoes sample stored under regular air temperature were a significant difference at p<5% with tomatoes stored in ZECC .This indicates that, tomatoes were increase in weight loss at room temperature and discard at ninth days ,whereas ZECC could be least in weight loss of red tomatoes and relatively better maintained of weight loss was observed. Weight (water) loss is the principal cause of fruit softening and shriveling. The average percentage of weight loss in regular air storage room were 4.84% at the end tomatoes life in ninth days, while in ZECC tomatoes were alive for fifteen days with a minimum average loss 3.06%, that was less as compared with the nine day loss of room temperature during storage period. Since, these days counted were tomatoes purchased from market shelf up to end of storage treatment period and if tomatoes were obtained from field, it might be stayed for 15-20 days with maintained fresh tomatoes quality attributes.

According to figure 3, the percentage loss of weight recorded of green stage at 9th day was 5.98%; whereas the weight loss in percent recorded from green stage tomato stored at ZECC 15 days were 2.29% with having the same initial weight. This shows that how the better maintenance of weight losses achieved in the cooling chamber. This could be attributed to the fact that the rate of respiration varied directly with temperature. This implied that the higher the temperature, the higher would be the respiration and moisture losses leading to weight loss and shrinkage. The differences in temperature and relative humidity as influenced by thermodynamic properties of both the components as well as construction features of the storage structures. The temperature inside ZECC were reduced which causes weight loss and inhibited softening of tomato as compared with regular air storage room. In developing countries, Storage has been observed to pose a greater threat to fruits and vegetables because information on the storage temperature, humidity requirements and the length of time they can be kept without a decline in market value is either inadequate or unknown to those who need the information.

Based on the current research findings the post harvest loss fruit and vegetables were reduced by 27.5% (by taking the differences of average value of tomatoes stored under room and ZECC at both green and red stages) via ZECC technology. This implied that from one ton (10,000 kg) fruit and vegetable 2750 kg of fruit and vegetables well maintained from losses via ZECC technology. This showed that, economically producers were benefited from loss of 55000 E.t birr based on the current market value of fruit and vegetables.

Effectiveness of Pot in Pot (PIP) storage in reducing environmental temperature and reducing weight loss of tomato

As shown in figure 4 there was temperature fluctuation between the ambient temperature and PIP refrigerator. The fundamental performance pot in pot (PIP) refrigerator was first investigated from the daily environmental temperature variations. An increase in outside temperature leads to decreased the inside temperature of the PIP refrigerator.

The maximum values of the outside and inside PIP refrigerator temperatures were 35°C and 8°C, respectively. Conversely, the minimum values of the outside and inside PIP refrigerator temperatures were 13°C and 7°C, respectively.

The degree of temperature reduction somehow depends on watering conditions. As shown in figure 5 the storage temperature of PIP refrigerator was reduced the environmental temperatures by a maximum difference of 26°C. This reduction in temperature was contributed to the extending of tomato shelf life from 6 days in the regular air temperature to 15 days under PIP refrigerator storage. The effectiveness of the system lies on the timely watering and environmental weather conditions, which means dry and hot environment increased the effectiveness of the cooling chambers. This might be attributed to the fact that low temperature and high relative humidity is obtainable within its cooling chamber for longer period of time. Postharvest diseases cause considerable losses to harvested fruits and vegetables during transportation and storage (Ambuko et al., 2017).

As shown in figure 6 weight loss of tomato stored under pot in pot cooling chamber was significantly lower than weight loss of tomato stored under regular air.

The most important factor in maintaining quality and extending the shelf-life of fruit and vegetables after harvest is temperature. Most of the physical, biochemical, microbiological and physiological reactions contributing to deterioration of produce quality are largely dependent on temperature. Metabolic processes including respiration, transpiration and ripening are particularly temperaturedependent. Generally, rates of biological reactions increase by a factor of 2 or 3 for each 10 °C increase in temperature. In the present case, excess CO2 was associated with loss of firmness, and with enzymatic tissue browning in tomatoes. Enzymatic browning is often associated with cell membrane damage in outer tissues, which is in turn associated with very high CO2 concentrations.

Once membrane integrity is lost, phenolic compounds normally present in cellular compartments are exposed to O2 and oxidized by the catalyzing activity of polyphenol oxidase liberated by the degrading membrane. Increasing the ambient temperature also increase the relative humidity inside the PIP refrigerator. The transpiration rate of fresh produce increases with water vapor deficit. The high rate of transpiration accelerated produce weight loss. Furthermore, increased temperature and a resultant increase in metabolism of the microorganisms favour decay (Tano, 2007). The highly perishable ones like tomato even in storage, has a recommended refrigerated storage life of less than one week. This is because they constitute mostly water. Loss of water from produce is often associated with a loss of quality, as visual changes such as wilting or shriveling and textural changes can take place. Another aspect to consider when handling fruits and vegetables is the relative humidity of the storage environment. Low temperature and high humidity slows respiration (ATP production). It means a fruit can stay longer. Ethylene action, transpiration, ripening and senescence are reduced. It also reduce the rate of water loss, slow or inhibit the growth of molds and bacteria slow the rate of the production of ethylene or minimize the product’s reaction to ethylene and other metabolic activities (Pan et al., 2019).

The loss in weight was recorded at 3 days interval until 15 days which served as the final weight. As shown in figure 6 there was significant difference in weight loss between regular air and pot in pot stored tomatoes. As shown in figure 7 tomatoes stored under pot in pot (A) are significantly fresh compared with tomato stored under regular air (B) which is spoiled.

Based on the present research finding, it could be conclude that construction of ZECC and pot in pot evaporative coolers were successful. ZECC effectiveness in reducing environmental temperature was observed. In addition to this tomatoes stored under ZECC showed better color and weight maintenance which is indicator for freshness and better storage life.

The ZECC can maintain relatively low inside temperature and high relative humidity as compared with outside temperature and relative humidity. Temperature inside the ZECC can be reduced through the process of an evaporative cooling mechanism and by using a shading curtain to protect the ZECC against direct exposure to solar radiation. The moisture condition on the walls in the ZECC and the ground condition also help to maintain higher relative humidity.

Pot in pot refrigerator is the most effective internes of its cost and potential in reducing environmental temperature. For stallholder farmers in developing in Africa pot in pot refrigerator is highly recommended since it is simple to construct and the art of pottery is the oldest and known art of Africa.

Ambuko, J, Wanjiru, F, Cheminingwa, GN, Owino, WO, & Mwachoni, E (2017). Preservation of Postharvest Quality of Leafy Amaranth (Amaranthus spp.) Vegetables Using Evaporative Cooling. J Food Qual. 2017, 1-7.

Indexed at, Google Scholar, Cross Ref

Arah, IK., Ahorbo, GK., Anku, EK., Kumah, EK., & Amaglo, H (2016). Postharvest Handling Practices and Treatment Methods for Tomato Handlers in Developing Countries : A Mini Review. Adv Agric.

Indexed at, Google Scholar, Cross Ref

Basediya, A, Samuel, DVK., & Beera, V (2013). Evaporative cooling system for storage of fruits and vegetables - a review. 50: 429-442.

Indexed at, Google Scholar, Cross Ref

Hasan, A (2012). Going below the wet-bulb temperature by indirect evaporative cooling : Analysis using a modified e -NTU method. Appl Energy, 89: 237-245.

Olosunde, WA., Igbeka, JC., & Olurin, TO (2009). Performance evaluation of absorbent materials in evaporative cooling system for the storage of fruits and vegetables. Int J Food Eng. 5 .

Indexed at, Google Scholar, Cross Ref

Pan, Y, Li, X, Jia, X, Zhao, Y, Li, H, et al. (2019). Storage temperature without fluctuation enhances shelf life and improves postharvest quality of peach. J Food Process Preserv. 43: e13881.

Indexed at, Google Scholar, Cross Ref

Pandey, R., & Pesala, B (2016). Heat and mass transfer analysis of a Pot-in-Pot refrigerator using reynolds flow model. J Therm Sci Eng. 8: 031006.

Indexed at, Google Scholar, Cross Ref

Tano, K, Oulé, MK., Doyon, G, Lencki, RW, & Arul, J (2007). Comparative evaluation of the effect of storage temperature fluctuation on modified atmosphere packages of selected fruit and vegetables. Postharvest Biol Technol, 46: 212-221.

Indexed at, Google Scholar, Cross Ref

Citation: Kassa M.A et al. (2023). Evaluating effectiveness of evaporative coolers in reducing environmental tempera-ture and postharvest loss of tomato. AJFST. 14: 003.