Research Article - African Journal of Food Science and Technology ( 2025) Volume 16, Issue 1

Received: 16-Jun-2024, Manuscript No. AJFST-24-139283 ; Editor assigned: 18-Jun-2024, Pre QC No. AJFST-24-139283 (PQ); Reviewed: 02-Jul-2024, QC No. AJFST-24-139283 ; Revised: 08-Jan-2025, Manuscript No. AJFST-24-139283 (R); Published: 15-Jan-2025

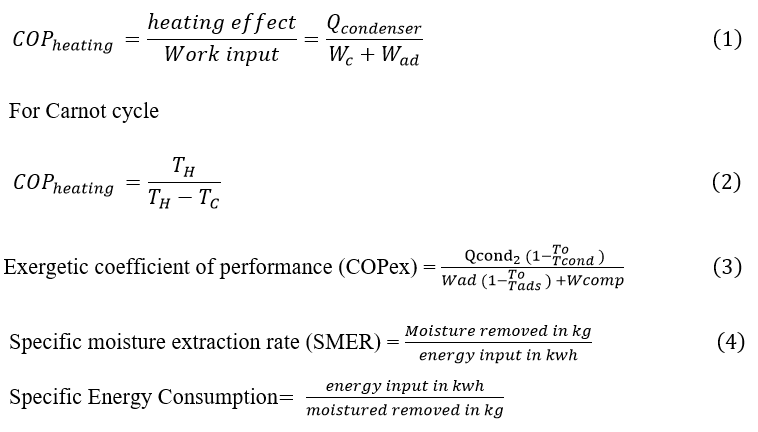

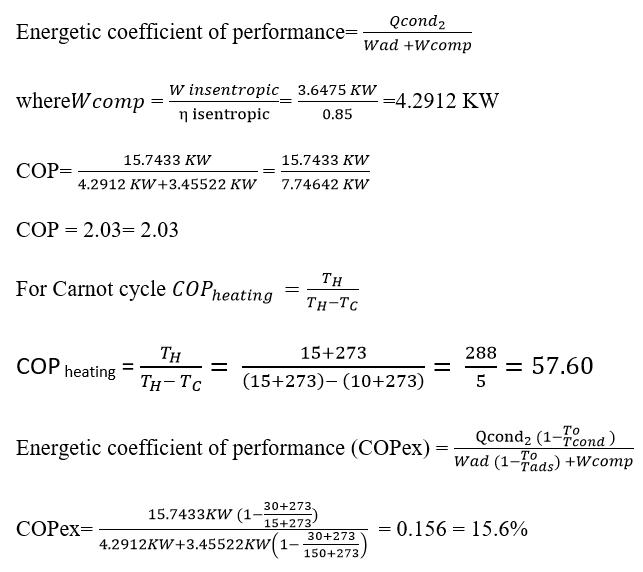

Drying is an energy intensive thermal process. Industrial processes may use heat pumps to recover low grade waste heat and utilize it for drying process. This current study aimed to evaluate the effect of varying air flowrate and thickness of tomato slices on the drying efficiency of the drying process at condensing temperature 15°C and evaporating temperature 10°C using Calcium chloride-ethanol as adsorbate-adsorbent pair. The energetic coefficient of performance, Carnot coefficient of performance for heating and exergetic coefficient of performance are 2.03, 57.60 and 15.6% respectively. For the drying analysis, the specific moisture extraction rate is 0.234 kg/kWhr and specific energy consumption is 4.27 kg/kWhr. The heat pump drying system modeled and simulated at a varied air flowrate and thickness of tomatoes serves as predictive tool to determine the efficiency of the drying process and how to determine the optimum condition. Thus, it can be concluded that as the air flowrate increases or thickness of tomato slices decreases, the drying efficiency also increases.

Coefficient of performance, Exergy efficiency, Specific moisture extraction rate, Specific energy consumption, Chemisorption, Thickness, Air flowrate

Tomatoes (Lycopersicon esculentum) are the second most significant vegetable after potatoes, due to their widespread cultivation and health benefits (Abano EE et al., 2011). In the processing of agricultural resources, drying is an important step (Correia AF et al., 2015). It not only assists in addressing the agricultural sector's post-harvest difficulties, but it also reduces the bulk volume of materials to a reasonable level (Chan WC et al., 2011). Heat pump drying is one of the most efficient and controllable means of drying wet materials (Fayose F et al., 2016). Heat pumps have long been recognized as an effective means of energy recovery (EL-Mesery HS et al., 2017).

The rapid rise in energy costs, supply security concerns, pollutant emissions, and global climate change have all rendered heating systems unsustainable in their existing forms, both now and in the future (Jimenez T, 2015). To tackle these issues, alternative heating solutions that focus on reducing energy consumption and improving heating performance while reducing negative impacts or negative influence on the environment must be investigated (Kivevele T et al., 2014). Heat pumps have long been recognized as an effective means of drying and energy recovery (Korhammer K et al., 2017). During the operation, a heat pump will be used to dry the difference between the hot heat produced by the condenser and the cold heat produced by the evaporator (Jensen JK et al., 2014). The hot heat produced by the condenser will be supply heat require for drying of the material (Sannan S et al., 2020).

The utilization of waste heat as a driving energy in an adsorption heat pump not only recovers energy that would otherwise be wasted, but also provides a system with low operating costs (Soni J et al., 2012).

Thermally driven heat pumps can use renewable energy sources such as solar, waste heat and geothermal energy (Ursula K et al., 2015).

Hybrid adsorption-compression heat pump concept allows a thermally activated sorption heat pump to operate at lower waste heat temperatures, extending its operating range. This improves the number of usable waste heat sources and gives the heat pump additional operational flexibility.

In this present study, the effect of varying drying process parameters such drying air flow rate, and thickness of tomato slices on drying efficiency of adsorption-compression hybrid heat pump drying system for heating process and drying of tomatoes slices were investigated through energy analysis, exergy analysis, and drying analysis using ASPEN PLUS simulation model.

Adsorption-compression hybrid heat pump drying system

The hybrid heat pump drying system consists mainly of two subsystems: Adsorption-compression hybrid heat pump and a drying chamber. The hybrid heat pump extract and transfer heat from natural heat sources in the surroundings (such as the air, ground or water), or from industrial or domestic waste, or from a chemical reaction or dryer exhaust air through adsorber and evaporator (Figure 1). The heat released by the first condenser is transferred to the second evaporator in which the heat-pump working fluid is vaporized. The compressor increases the pressure of the working fluid, which in turn increases the condensing temperature. The working fluid condenses in the second condenser, delivering high-temperature heat to the process stream that is being heated or sent to the drying chamber.

Figure 1. Schematic diagram of adsorption-compression hybrid heat pump.

The heat from exhausted air from the dryer that is cooled and dried is recirculated back to first evaporator of the heat pump where it is cooled and the moisture in the air is condensed and removed. The cool and dry air from the evaporator then goes into the condenser of the heat pump and is heated. The hot and dry air then enters the dryer and absorbs the moisture in the materials being dried in the dryer and becomes exhausted air at the outlet of the dryer, and the cycle repeats. Because the heat pump retrieves the heat in the exhausted air to heat the air entering the dryer while it removes the moisture in the exhausted air, it achieves a high energy efficiency in the drying of biological materials such as tomato slices which are thermally and oxygen sensitive.

Coefficient of performance for heating COP heating is given as:

The tomato slices at room temperature are assumed to be a solid mixture of the components in Table 1. The physicochemical properties of the tomato were created in ASPEN PLUS environment. The drying air temperature is assumed to be 40°C. The initial and critical moisture content are assumed to be 0.1 and 0.01 respectively. Thickness and radius of tomato slices are assumed to be 2 mm and 2 cm respectively. The number of tomato slices dried per turn (N) is assumed to be 12,000 slices. Dimension of the dryer is assumed to be 61 cm × 61 cm × 61 cm. It is a modified drying chamber whose volumetric compartment can be increased as number of tomato slices increases. The flowrate of tomato slices and air are assumed to be 400 kg/h. and 200 kg/h. Flowrate of the working fluid is 1kmol/hr. and isentropic efficiency of compressor is 85%. The exergy reference temperature and pressure were assumed to be 30°C and 1 atm respectively.

Tomato components

The main components of tomato are their percentage composition are shown in the Table 1.

| Components | Percentage of composition |

| Protein | (%) 2.01 |

| Ascorbic acid | (%) 2.50 |

| Ascorbic acid | (mg/100) 19.33 |

| Phenolic compound | (mg/100) 30.5 |

| Carotene | (mg/100) 13.56 |

| Lycopene | (mg/100) 0.51 |

| Moisture (water) | (%) 94.60 |

Table 1. Components of tomato and their percentage composition.

Modelling of CSTR adsorber in ASPEN PLUS.

The Table 2 below gives the kinetic parameters for modeling CSTR adsorber using ASPEN PLUS;

| Parameter | CaCl2- C2H5OH |

| adsorber pressure (kPa) | 680 |

| adsorber temperature (°C) | 180 |

| k (mg/min) | 0.14 |

| n | 2 |

| Reaction time (min) | 27 |

| Ea, ads (kJ/mol) | 50 |

Table 2. Kinetic parameters obtained from the reaction of the adsorbent-adsorbate pair for modeling chemisorptions adsorber using CSTR reactor.

Below are the given steps for modeling CSTR adsorber using ASPEN PLUS;

•Specify the operating condition (temperature,pressure, volume and valid phase of the reactor),specify the adsorption kinetics (n (order ofreaction), k (kinetic rate reaction constant), e(activation energy), t (reaction temperature andreaction equation and state). Driving force,concentration exponent) specify the adsorptionequilibrium (temperature approach to equilibriumand reacting phase).

•Specify generalized langmuir hinshelwood hougenwatson adsorption parameters (adsorptionexponents, adsorption constant, concentrationexponent).

The thickness of tomato slices is varied at condensing temperature 15°C and evaporating temperature 10°C using ethanol as working fluid to determine its effect on the performance of hybrid heat pump drying system as shown below

Air flowrate=200 kg/h. Tomato flowrate=400 kg/h.

Dimension of the dryer is assumed to be 61 cm × 61 cm × 61 cm

Volume occupied by the tomato is assumed to be two-third of the volume of the drying cabinet

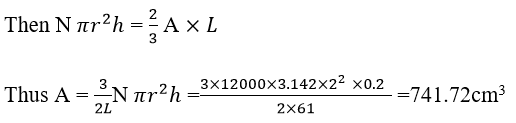

Volume of the drying Cabinet=drying area× height of dryer The volume of a slice of tomato is assumed to be equal to volume of cylinder =πr2h

The thickness of the tomato slice (h) is assumed to 2 mm

The radius of a tomato slice (r) is assumed to be 2 cm

The number of tomato slices dried per turn (N) is assumed to be=12,000 slices

Total volume of tomato slices=N πr2h

If volume occupied by the tomato is assumed to be two-third of the volume of the drying cabinet

For the same number of tomato slices dried per turn

When the thickness is doubled (4 mm) the drying area =1483.44 cm3

When the thickness is tripled (6 mm) the drying area =2225.154 cm3

When the thickness is 8 mm the drying area=2966.87 cm3

When the thickness is 10 mm the drying area=3708.59 cm3

The drying air flowrate was varied between 100 kg/h and 200 kg/h.

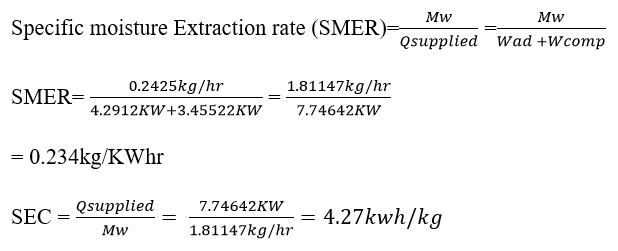

Effect of varying tomato thickness on the performance of hybrid heat pump drying system (Table 3,4 & Figure 2-5).

| Thickness (mm) | Water removed (kg/h) | SMER (kg/KWh) | SEC (KWh/kg) |

| 2 | 1.81147 | 0.2338 | 4.2772 |

| 4 | 1.38083 | 0.1783 | 5.6085 |

| 6 | 1.16623 | 0.1506 | 6.6401 |

| 8 | 1.03072 | 0.1331 | 7.5131 |

| 10 | 0.93483 | 0.1207 | 8.285 |

Table 3. Effect of varying tomato thickness on the performance of hybrid heat pump drying system.

Figure 2. Effect of thickness of tomato slices on amount of water removed during drying.

Figure 3. Effect of thickness of tomato slices on specific moisture extraction rate and specific energy consumption.

| Air flowrate (kg/hr) | Water removed (kg/hr) | SMER (kg/KWhr) | SEC (KWhr/kg) |

| 100 | 0.69042 | 0.08913 | 11.2196 |

| 125 | 0.94429 | 0.1219 | 8.2034 |

| 150 | 1.21746 | 0.1572 | 6.3613 |

| 175 | 1.50721 | 0.1947 | 5.1361 |

| 200 | 1.81147 | 0.2338 | 4.2772 |

Table 4. Effect of varying air flowrate on the performance of heat pump drying system.

Figure 4. Effect of air flowrate on specific moisture extraction and specific energy consumption.

Figure 5. Effect of air flowrate on amount of water removed during drying.

The heating effect of the heat pump is 15.7443 KW. The thermal compression by adsorbed reduces the work done by the mechanical compressor, which reduces the energy loss in the compressor and improve its performance. The energetic coefficient of performance, Carnot coefficient of performance for heating and energetic coefficient of performance are 28.8 2.03, and 15.6% respectively. For the drying analysis, the specific moisture extraction rate is 0.234 kg/kWh and specific energy consumption is 4.27 kg/kWh. These values show the system has good drying efficiency and also reveal the profitability and commercialization of the drying system respectively. Figure 2 and 3 show that as air flowrate increases amount of water removed per hour increases, specific moisture extraction rate increases while specific moisture energy consumption decreases. Conversely figure 4 and 5 show that as the thickness of tomato slices increases, the amount water of removed per hour decreases, specific moisture extraction rate decreases while specific energy consumption increases. Thus, as the air flowrate increases or thickness of tomato slices decreases, the drying efficiency also increases.

Despite their great value, tomatoes are prone to rot and loss during their season, thus they must be dried after harvesting to extend their shelf life and preserve them, as it allows for longer storage times, less packaging, and lighter shipment. The heat pump drying system modeled and simulated at a varied air flowrate and thickness of tomatoes slices serves as predictive tool to determine the efficiency of the drying process and how to determine the optimum condition. Thus, it can be concluded that the air flowrate increases or thickness of tomato slices decreases, the drying efficiency also increases.

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

Citation: Isola, Olakunle, Olawale (2024). Effect of Varying Drying Air Flowrate and Thickness of Tomato Slices on its Drying Process Using a Modeled and Simulated Heat Pump Drying System. AJFST. 16:01.