Research Article - International Research Journal of Engineering Science, Technology and Innovation ( 2023) Volume 9, Issue 4

Received: 01-Aug-2023, Manuscript No. irjesti-23-110472; Editor assigned: 04-Aug-2023, Pre QC No. irjesti-23-110472(PQ); Reviewed: 18-Aug-2023, QC No. irjesti-23-110472; Revised: 21-Aug-2023, Manuscript No. irjesti-23-110472(R); Published: 31-Aug-2023, DOI: 10.14303/2315-5663.2023.121

The sun's energy is the finest option for thermal energy generation because it is available all over the world and is free to use. Poultry egg incubation is requiring a continuous supply of energy for efficient performance and operation. On-grid power does not reach Ethiopia's rural areas, and even in those areas where it is available, electricity might be irregular or switched off at any time, causing incubators to malfunction, limited production, and expensive costs. The Use of generators increases the running cost of incubators and the Natural incubation process by hen produces a very small number of chickens. A solar-powered egg incubator with a thermal energy storage system was built, modeled, and tested in this study to assess its performance. A solar egg incubator was developed utilizing a solar collector with built-in sensible solid heat storage (placed below the absorber plate), a 50 eggs capacity incubation chamber, and a control unit. During the incubating period, there is sufficient sunlight that is converted into the energy required for a solar-powered egg incubator by a flat plate solar collector in the study area. The result showed that on the highest solar radiation days (629.3w/m2) the average outlet collector temperature was 53oC and 37oC was obtained on the lowest solar radiation days (397.5w/m2). The maximum collector thermal efficiency was found to be 44.33 %. A total of 20 eggs were tested for both fertility and hatchability over 21-days in a solar-powered egg incubator. The incubating chamber was maintained by using a temperature controller (thermostat STC 1000) throughout the incubating period within a temperature range of 36.5 to 39.5 o C and a relative humidity range of 40 to 75 %. The percentage fertility and hatchability of eggs were 61.11% and 27.27 % respectively.

Collector, Incubator, Poultry, Performance, Sensible storage, Solar energy

Numerous types of egg incubators were designed and developed by various researchers, by using several different sources of energy. An incubator could be mainly used for five types of energy sources; electrical, biogas, solid fuel (charcoal), fossil oil (kerosene or gas, diesel-based generator), or solar types based on the source of energy (Kifilideen L Osanyinpeju , 2016). The incubators having solid fuel, fossil, oil, or biogas as their source of heat generate soot and other combustion products show that the lower percentage of hatchability of eggs (Kifilideen L Osanyinpeju , 2016). Chipped away at extending domesticated animals’ creation in Nigeria, including the advancement of savvy bird-egg hatchery models. In their model, which included the use of still air and oil lamps as sources of heat for the egg incubator, they found that the still-air incubator is the most time-consuming, with a hatchability rate of 33% (A Agboola, 2013).

According to the accomplished work on development and evaluation of a passive solar-powered system for poultry egg Incubation’ electricity supply in developing counties like Nigeria has remained inadequate and unreliable alternative methods of meeting the energy needs in agriculture and also the poultry industry specifically (A Metwally, 2020). As properly as they mentioned that there's a disadvantage the usage of solar thermal collectors, warm water, air, oil, or different flowing materials, and that heated cloth can't without a doubt be placed right into a battery, not like the power generated via way of means of a solar panel can do. The problem along with his system is how the thermal storage unit would be able to store and release the warmth when the sunset and particularly on days when the sun is hidden behind clouds.

The research carried out on the ‘Development of solar collectors combined with thermoelectric modules for solar drying technology has been successfully developed, analyzed, and see-beck effect is applied (KL Osanyinpeju, 2018). It means that the heat energy is converted directly into electricity. The goal of this study is to develop a sun drying technology that incorporates a solar collector and a Thermoelectric Generator module (TEG). Solar collectors can be the operator and produce hot air temperatures of about 70-80degree Celsius. The common bottom temperature of the collector is 45.4 Celsius, in which the ambient temperature becomes 35.4 Celsius, in regions with snow or no sunshine, masses of clouds or tree corners, dusty floral, etc.

The study on performance evaluation of mono-crystalline photovoltaic panels in Funaab, Alabata, and Ogun State, Nigeria weather condition was carried out and this study recommended that performance test must be carried out on the solar panels whenever it’s to be used to power any load (egg incubator) to ensure that the provide solar PV solar panel would be able to produce the power required to power the load (egg incubator) without failing (Kifilideen L Osanyinpeju, 2018).

Almost in all literature reviews presented, the researchers expend their effort on the design and modeling as well as on the performance evaluation of different types of incubators, However, only a few of them deal with the solar integrated thermal energy storage for an egg incubator and efficient use of energy in the system. Thus, in this research, the researcher aimed to make an experimental evaluation of solar-powered egg incubator with integrated thermal energy storage and provide for the community. This will reduce the energy bill and help to use. In addition to that, it will reduce the load from the national grid and increase the need for a community to use clean energy for almost all applications of incubations.

Description of experimental site

The experiment was carried out at the Bako agricultural research center, which is located 250 kilometers west of Ethiopia's capital city, Addis Ababa. Specifically, it is located at geographical coordinate 9°06’ N-latitude, 37°09’ E -longitude, and at an altitude of 1650m above mean sea level with a total population based on the Central Statistical Agency of Ethiopia (CSA) is about 184,925 in 2017 G.C.

Materials

• Materials utilized and equipment used in this experiment includes:

• Absorber plate

• Glazing Glass

• Pan made from Mild steel

• Ply wood

• Rock pebbles

• Mesh wire

• Thermometer

• Infrared thermo meter

• Control valve

• Thermostat

Description of the System

This schematic diagram of a solar-powered egg incubator integrated with a thermal energy storage system considered. The main components of the system are the incubating unit, flat plate solar collector with built-in thermal energy storage system, and temperature control device set (thermostat set). Incubating cabinet was made up of 2 mm thick galvanized sheet metal, lined at the edge with plywood. The external length, width, and height of the outer box are 50 cm, 50 cm, and 57 cm respectively, the space between the inner box and outer box is filled with straw foam to reduce heat losses (Figure 1).

For the collector, the casing was made of plywood and the inner box was constructed using 2mm aluminum thick painted black to increase its absorption. A fiberglass substance fills the area between the outer box and the inner box was about 40 mm thick to reduce heat losses. The airflow channel (upper compartment) is located between the absorber plate and the transparent top cover, while the thermal storage unit (lower compartment) is located between the absorber plate and the backplate. The overall length, width, and height of the solar collector are 1200 mm, 680 mm. and 250 mm respectively. The collector top glazing is a single-layer transparent glass sheet of 4 mm in thickness. The thermal storage contains rock pebbles of 145.5 kg.

METHODOLOGY

This study was conducted to evaluate experimentally an incubator that uses solar energy and integrates thermal energy storage for poultry production, to achieve the objective of this work, surveying the literature from related work, referring to the journals, books, and other unpublished material that were conducted. Direct solar radiation measurements during an experimental test were done. The experimental test was performed under normal weather conditions at Bako agricultural engineering research center and the result was evaluated. Before loading the physical tests were conducted. This was done for 24 hours and some modifications were done on the solar-powered system to avoid intermediate failure during the incubation period. A total of 25 eggs were purchased while 20 eggs were successfully loaded. 2 eggs out of the 20 eggs loaded were broken during the Candler test conducted on the 5th day. More so, the inner temperature of the incubator was monitored using a temperature controller (thermostat STC 1000 China model), and relative humidity was measured using the digital thermo hygro-thermo meter. Temperatures of different components of the solar collector and solar radiation were measured during 21 days of incubation. Those days data were taken to study the effects of the solar collector temperature on the incubator chamber without any active supplementary heating system attached to it.

The measurement data have taken for 10 hours, beginning from 8:00 to 17:00 in the 1 hours’ time intervals. The hourly temperature measurements were done by using k-type thermo-couples fixed at the absorber plate used to measure the temperature of the collector (Tp), at storage (Ts), and other k type thermo-couple were attached at the outlet of the solar collector to measure hot air at collector outlet (To). These temperature values are read from the table at the millivolts of the thermocouple. While the hourly solar radiation was measured for 21 days of the incubation period (Figure 2).

In order to measure beam radiation, the black-coated horizontal flat plate is used. The one plate is placed directly to solar irradiance. Then measure the temperature of the black surface for both plates within the time intervals by an infrared thermometer without touching (Figure 3).

During this experiment, the loaded eggs were turned five times daily at intervals of 3 hours to avoid egg yolk from sticking on the shell. However, the turning of the eggs was stopped after day 18 to allow the embryos time to start piping (BO Bolaji, 2020).

Candling is a technique used to notice the development and advancement of an incipient organism inside an egg which utilizes a brilliant light source behind the egg to show subtleties through the shell (A Mahapatra, 2019). A Candler was utilized to decide the rate richness of the eggs on the 5th day, 14th day, and on the 17th day where in break, fruitless, and dead undeveloped organisms were recognized (BO Bolaji, 2020)(KL. Osanyinpeju, 2018).

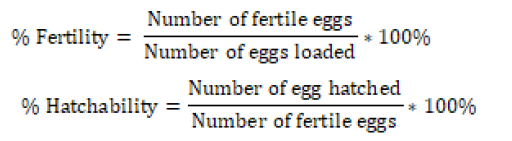

The percentage fertility and hatchability were obtained from the equations below respectively.

Design calculation

Total heat requirement in incubator:

The total heat requirement of the incubator (����) is the summation of the heat energy required to raise the temperature of air (����) and egg (����) from 220C to 37.5°C; the heat loss through the wall of the structure (����), egg tray and ventilation (����).

In determining the heat load of the egg incubator, the following assumptions were made:

Incubator materials have a constant thermal conductivity

The incubator is a closed system at a constant temperature.

The required incubator temperature is 37.50C

The room temperature is 220C

The required humidity is 60%

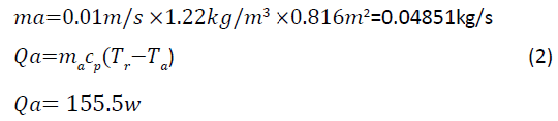

Heat required raising the temperature of the air on the incubator:

Measured air was flowing at the average velocity wind of 0.01��/�� with density 1.22����/��3 and per unit area.

Heat required raising the temperature of egg on the incubator:

The average mass of one egg was weighed and found to be 60 g and the specific heat capacity of the egg was taken to be 3.18 KJ ⁄ Kg k

This is the total heat required to raise the temperature of the eggs from 220C to37.50C. So, the total heat required for 50eggs =3.08KJ×50=154 KJ

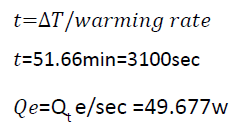

This is the total heat required to raise the temperature of the eggs from 220C to 37.50C. But this type of heat is provided gradually to prevent the eggs from boiling. Eggs transferred directly from the storage room to the incubator are heated at a rate of 0.30°C/min. whereas the pre-warmed eggs warmed at rates of 0.13°C and 0.16°C/min for the storage to room and room to incubator treatments, respectively. Now we considered our egg directly from storage with room temperature 220C the time required to raise this temperature to the incubator temperature is calculated.

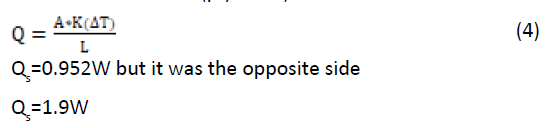

Heat loss on both sides of the incubator:

The heat loss on both sides of the incubator can be calculated because they have the same surface area and are composed of the same material (plywood).

Heat loss at the top and bottom surfaces of the incubator:

The top and bottom surfaces of the incubator were equal and opposite made of the same material. Area, A=0.262��2. Since there were two equal surfaces,

A= 2×0.262��2=0.524��2

Qbt=1.9W

Heat Loss at the Front and Back of the Incubator:

Qfb=1.9w

Therefore, the total heat loss: Qloss=(1.9*1.9*1.9)=6.86w

Heat required raising the temperature of egg tray (structure) on the incubator:

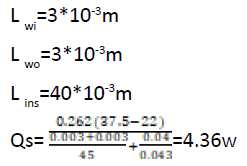

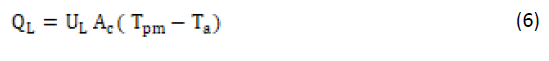

There is an outer and inner box built from galvanized sheet metal of ��=45��/����−1. In between the wooden boxes is an insulation material (fiberglass) of ��=0.043��/����−1

���� was calculated using the equation:

Where, As=0.262m2

There are four similar sides in the structure so total Qs=4.36*4=17.46 w

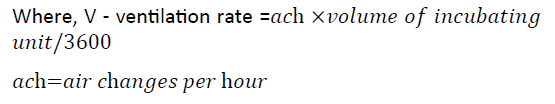

Heat loss through ventilation (Qv):

Qv was calculated using equation

Therefore, the volume of the incubating unit (v) =0.149m3

A suitable value of 2 air changes per hour was chosen.

Therefore, the ventilation rate =2 ×0.149m3/3600=0.827 ×10−4��3/��

Flat-plate solar collector

Solar collectors are used to converting direct and diffuse radiation from the sun into thermal energy. its special quite device transforms alternative energy to heat. Energy is moved from an abroad wellspring of energy to a liquid. The energy gained by the solar collector can be expressed by the following relation[8]:

Where, Ac = area of transparent cover (m2)

It= total incident radiation collector surface (W. m– 2)

UL=overall heat loss for the collector (W. m– 2.K– 1)

α=solar absorptance

τ= transmittance

Tc=collector temperature (K)

T=ambient air temperature (K)

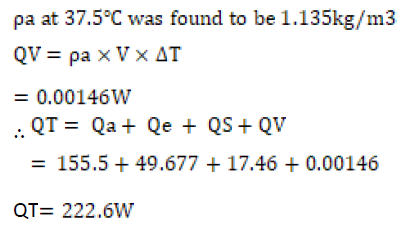

Overall loss coefficient and heat transfer correlations:

According to an insightful perspective, it is helpful to utilize the complete misfortune coefficient characterized by the recipe to communicate the warmth misfortune from the authority.

Where Tpm - the average temperature of the absorber

The heat lost from the collector is the sum of the heat lost from the top, the bottom, and the sides. Thus,

Each of these losses is also expressed in terms of coefficients called the top loss coefficient, the bottom loss coefficient, and the side loss coefficient

Top loss coefficient:

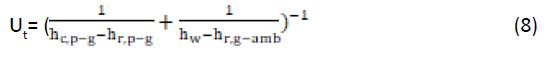

The upper misfortune coefficient Ut is assessed by considering the convection and re-radiation loss of the assimilation plate the vertical way. It is assumed that the temperature drop in the thickness of the roof is negligible, and the interaction between the incident solar radiation absorbed by the roof and the emission loss is negligible. The outgoing re-radiation is long-wavelength. For these wavelengths, the transparent cover will be assumed to be almost opaque.

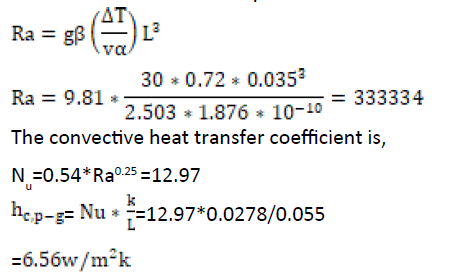

Based on the maximum plate temperature is 73oC and cover glass temperature is 43oC. The mean temperature between them is 58oC, so the air properties on this temperature: the property of air at 58oC is not available on-air property table so it was calculated by interpolation. The value obtained was:

ρ (density of air) =1.065kg/m3

Cp (specific heat of air) =1007KJ/kg*k

K (thermal conductivity) =0.027934w/m*k

α (thermal diffusivity) =2.503*10-5m2/s

ν (kinematic viscosity) =1.876 *10-5m2/s

μ (dynamic viscosity) =1.988*10-5kg/m.s

pr (Prandtl number) =0.72

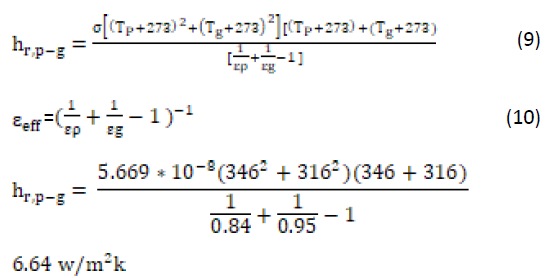

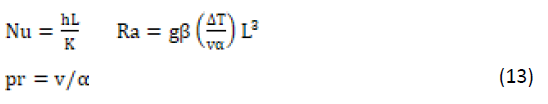

Radiative heat transfer coefficient:

From the plate to the cover:

The radiative heat transfer coefficient from the plate to the glass cover is expressed as:

From cover to the ambient:

The effective temperature of the sky is usually calculated from the following simple empirical relation in whom temperatures are expressed in Kelvin

The radiative heat transfer coefficient from the glass cover to the ambient is expressed as:

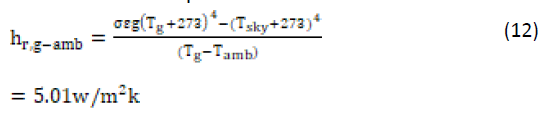

Convective heat transfer coefficient:

From the plate to the cover

The natural convection heat transfer coefficient h1c is related to three dimensionless parameters, the Nusselt number Nu, the Rayleigh number Ra, and the Prandtl number Pr, that are given by:

h- Heat transfer coefficient [W/m2 K,L– is the plate spacing,(0.35),g–The gravitational constant, – is the volumetric coefficient of expansion of air.

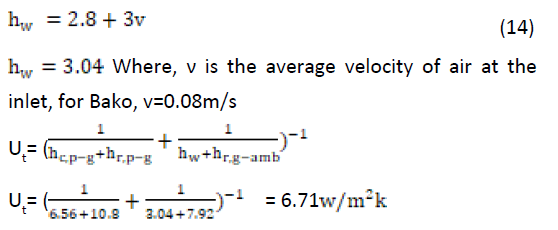

Wind heat transfer coefficient is given as

Bottom heat loss coefficient:

Assume that the heat flow is one-dimensional and stable. In most cases, the thickness of the insulation provided causes conduction-related thermal resistance to dominate. Therefore, ignore the resistance to convection at the bottom of the collector casing:

Where Ki - thermal conductivity of the insulation, - back insulation thickness

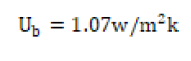

Side loss coefficient:

As on account of the base misfortune coefficient, it was accepted that the conduction obstruction overwhelms and that the progression of warmth is one-dimensional and consistent.

Where: A1- P*d e=3.68m2

P – the perimeter of the absorber plate. (m)

de – the height of the edge. (0.64m)

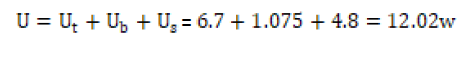

Overall heat coefficient:

The overall heat loss coefficient UL is the sum of the top, bottom, and edge loss coefficients. That is:

Over all heat loss

Assume; mean temperature of collector 43oC and mean air temperature is 22oC

QL=12.02(43-22)=252w

Where, Ta = air temperature and Tm = mean temperature of the collector

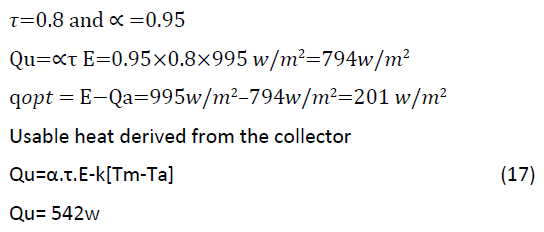

According to metrological data, the annual average daily radiation in an area reaching the ground is; E=6.01kwh// m2/day*day/6h=995w/m2.To change E into w/m2 average sunshine hour 6 hr. One part of the heat is transmitted due to cover glass and absorptive surface material selection for cover glass is Plexiglas

Usable heat derived from the collector

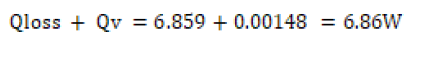

The thermal efficiency of the collector is defined as the ratio of useful energy gain by the air to the solar radiation incident on the absorber of the solar collector[1].

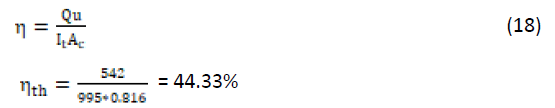

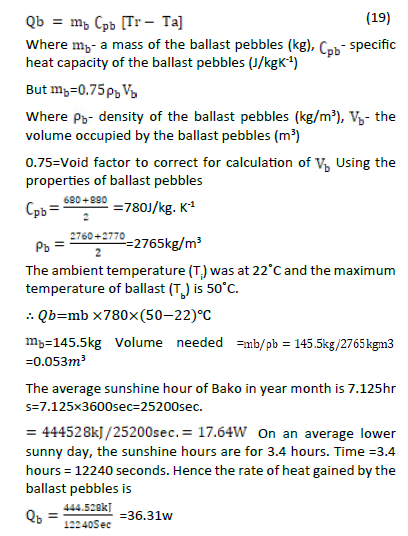

Thermal storage capacity:

Once the incubator is maintained with the required temperature the amount of heat supply is equal to the sum of heat loss through the incubator and ventilation loss

This is continuously supplied for 21 days. The total amount of energy stored on storage material = 6.86W ×use time 18hour×3600sec=444.528KJ.

The amount of heat that can be stored by the ballast pebbles (Qb) was calculated as shown below:

Experimental results on solar beam measurements

The experiment was conducted for 21 days under normal weather conditions of the study area in may (05, 10, and 15, 2021) for eleven hours per day. The selection of days was based on the intensity of solar radiation estimated before experiments (i.e. highest, lowest radiation, and monthly average daily solar radiation). The measured data for three days was recorded. The following figure shows the variation of beam obtained from measured temperature by the black painted plate at the same time interval in three day (Figure 4).

The maximum values of the beam solar radiation observed during the experiment are 669.7 W/m2 at 13:00 May 05,2021 and the minimum values of beam radiation obtained May 10.2021 at 8:00 am. The results of solar thermal energy depend on the intensity of solar radiation, and the solar radiation may be affected by the weather condition such as the presence of clouds and the angles of sun forms to the earth. During the experimental studies, the weather condition of the study area for the first day of May 05 is a clear sky, sunny and no cloud was seen. For this purpose, relatively higher solar radiation was observed on this day. However, on May 15 sunny, but the small scattered cloud has seen about 9:00 am to 11:00 am. Additionally, on May 10, the Bako weather condition is a clear sky and sunny before and afternoon. However, the passing cloud was seen around solar noon (Figure 5).

A significantly similar solar radiation results between the experimental data and calculated. However, the experiment is conducted for a few days and it may be difficult to decide the monthly data by three-date data. The maximum average beam radiation observed from experimental and calculate are 613.3W/m2 and 716 W/m2 at 13:00 respectively.

Experimental results after loading egg into the incubator

During the experiment, various parameters were recorded in a variety of days starting from May 1 up to 22, 2021. Among those days’ typical data were taken for analysis for three days only (05, 11, and 15 May). The selection of days was based on the intensity of solar radiation (i.e highest, lowest radiation, and monthly average daily solar radiation). Results of measured collector outlet, ambient air temperatures, and a typical day of highest solar radiation (May 05, 2021): The variations of ambient temperature, collector outlet temperature, and solar radiation intensity for typical days of highest solar radiation, during 21 days of incubation are shown in. The maximum collector outlet temperature and maximum ambient air temperature obtained for the day of highest solar radiation were 550C and 270C during daylight at 12:00 am and 14:00 respectively, while the minimum values obtained for lowest solar radiation were 38oC and 200C during daylight respectively. During the test, a maximum collector thermal efficiency of 44.33% was obtained. The high temperature obtained in the solar collector helps maintain the design temperature of 37.50C in the incubating chamber with slight fluctuations between+20C and –2 0C throughout the incubating period (Figure 6).

Results of measured outlet air, ambient air temperatures, and lowest solar radiation day (May 10, 2021):

The variations of ambient temperature, collector outlet temperature, and solar radiation intensity for typical days of lowest solar radiations during 21 days of incubation are shown in Figure 7. The maximum collector outlet temperature and maximum ambient air temperature obtained for the day of lowest solar radiation were 480C and 25.50C during daylight at 12:00 am and 13:00 respectively, while the minimum values obtained for lowest solar radiation were 22oC and 15.10C during daylight at 18:00 and 24:00 respectively. During the test, a maximum collector thermal efficiency of 23.2% was obtained (Figure 7).The variation of the average temperature of the glass cover, absorber plate, and ambient air of experimental results for a test period from 8.00 AM to 17.00 is shown in (Figure 8). It can be observed that the variation of absorber plate temperature was dependent upon the solar radiation intensity, increased in the morning, reaching a peak in the noon, and gradually decreased in the afternoon. The maximum outlet air temperature was recorded to be 55°C at noon. The solar radiation intensity varied between 460–699.5 W/m2 during experimentation

Thermal efficiency of solar collector

As the solar intensity of the study area increases, more useful energy is captured. As the energy captured to increase the plate temperature raises and heat captured by the plate is partially transmitted to the storage compartments that were increased the temperature of the thermal storage systems. System thermal calculation results for the experimental measurements of average solar radiation in the time intervals to calculate the efficiency of the solar collector were discussed in the following figure (Figure 9).

Figure 9 depicts the variation of thermal efficiency and useful heat energy leaving the collector with the beam radiation throughout the monthly average day of May 15, 2021. During the experiment, from 8:00 am to 17:00, the beam radiation varies in the range of 460 W/m2 to 629.3 W/m2. Most of the time, the peak value of collector temperature is observed at maximum solar intensity about solar noon. The maximum thermal efficiency was found to be 44.33% at the maximum solar radiation intensity with storage and 43% with no storage materials at 13:00. When there is no energy storing material, the maximum temperature reached by air is comparatively less and during the evening there was a high fall rate in the temperature, at that time the efficiency of the system falls with the fall of temperature. No-load efficiency of 66.95% has been reported by (AA Gatea, 2012) in natural convection solar collectors. Further, (P Gbaha, 2006) have reported the thermal efficiency of flat plate collectors to be 62% at an airflow rate of 0.03 kg/m2s.

The instantaneous efficiency was found to be decreasing with time. The efficiency is a function of the temperature difference between plate and air as well as air and glass cover as shown in Eq. (L De Smit, 2006). With increasing time, the temperatures of the plate, air, and glass cover are also increasing; thereby, decreasing the values of (Tp- Ta) and (Ta-Tg). Again, the radiation intensity drastically reduced in the afternoon.

Candling test result

The percentage of fertility and hatchability of the eggs were calculated as shown in Table 4.6. The results obtained during the test show that out of 18 eggs set in the incubator 7 eggs were infertile. The percentage fertility of eggs was 61.11%. Also, out of 11 fertile eggs, 3 eggs were hatched, which resulted in a percentage hatchability of 27.27%. When compared to prior studies on incubator hatchability, the incubator was medium as the primary test. Using Tibetan and Dwarf chickens, (L De Smit, 2006) found a hatchability range of 26.23 percent–79.72 percent, whereas (TR Fayeye, 2006) found a hatchability range of 47 percent–76 percent using Fulani-ecotype birds. The hatchability of chicken eggs is influenced by a variety of parameters such as egg age, storage temperature, mother hen age, management and raising technique, mating method, incubation relative humidity, and egg rotation angle (E Stener-victorin, 2019). The eggs obtained from the farm have a high rate of infertility, which might be due to low fertility caused by the farm's frequent mating. Other issues such as incorrect mating ratios breeder age and poor management/social stress such as the insufficient floor feeding, and water space among others maybe at work (Table 1).

Candling check on the 5th day of incubation |

|||

|---|---|---|---|

| No of eggs | Development | Observation | Remark |

| 2 | Not visible | Clear | Infertile |

| 5 | Not visible | Large air space | Infertile |

| 7 | Visible at one end | Lines strolling across | Fertile |

| 4 | Visible on the center | Visible purple of red stains | Fertile |

| Candling test on the 14th day of incubation | |||

| 7 | Not visible | Clear | No development |

| 7 | Dark appearance | Clear air space | Development in progress |

| 4 | The whole egg is dark | No air space | Development has ceased |

| Candling test on the 17th day of incubation | |||

| 2 | Dark appearance | Beak is Visible | Development near completion |

| 1 | Dark appearance | Clear air space | Development in progress |

In this present study experimental evaluation of a solarpowered egg incubator with integrated thermal energy storage for the study area was carried out. The system prototype was constructed using locally sourced materials at Bako agricultural engineering research center laboratory and tested on latitude 9.06oN. The incubator is made up of a solar collector with built-in thermal storage and a 50-egg capacity incubation chamber. The first solar energy potential of the study area was measured. During the incubating period, there is sufficient sunlight that is converted into the energy required for a solar-powered egg incubator by a flat plate solar collector in the study area. The result showed that on the highest solar radiation days, the average outlet collector temperature was 55oC and 37oC was obtained on the lowest solar radiation days. The collector thermal efficiency was found to be 44.33 %. The fertility and hatchability of eggs were tested using a total of 20 eggs over 21 days in a solar-powered egg incubator. The incubating chamber was maintained by using a temperature controller (thermostat STC 1000) throughout the incubating period within a temperature range of 36.5 to 39.5oC and a relative humidity range of 40 to 75 %. The percentage fertility and hatchability of eggs were 61.11% and 27.27 % respectively. For the future, I have recommended that Detail cost analysis with material selection for better system performance, to get monthly and hourly data values of solar radiation for the study area by horizontal flat plate, measurements need for many days repeatedly, Further analysis and biological test needed to know the characteristics of egg embryo growth, and using all the necessary materials, the project is exactly profitable and developmental.

The authors would like to thank laboratory technicians of renewable Energy Technologies for their great contribution. In addition, would to thank Energy Engineering Team of Bako Agricultural Engineering Research Center for data collection that supported manuscript, contribution for preparation of paper and valuable comments and suggestions on research work and technicians of metal and wood workshops particularly Mr. Lelisa Tsageye and Mr. Habtamu for their emanate contribution for construction of technology. Finally, my thank goes to all stuff of Oromia Agricultural Research Institute for their financial support and comments in reviewing the manuscript throughout our chain.

Copyright: ©2023 International Research Journals This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.