Research Article - African Journal of Food Science and Technology ( 2022) Volume 13, Issue 3

Received: 05-May-2022, Manuscript No. AJFST-22-57995; Editor assigned: 07-Mar-2022, Pre QC No. AJFST-22-57995 (PQ); Reviewed: 20-Mar-2022, QC No. AJFST-22-57995; Revised: 24-Mar-2022, Manuscript No. AJFST-22-57995 (R); Published: 31-Mar-2022, DOI: http:/dx.doi.org/10.14303//ajfst.2022.011

Agricultural products of high moisture contents require appropriate drying method for nutrient component retention, particularly the bio-fortified crops, such as orange-fleshed sweet potato (OFSP). Different drying (oven, open sun, freeze drier, direct solar and indirect solar dryings) methods and slice thickness of 2 mm and 4 mm were applied in processing fresh OFSP samples to flour. The study determined stability of β-carotene (µg/g) dry weight (DW) in OFSP by different drying methods and slice thickness. The result revealed high beta-carotene retention ranging from 104.48 µg /g – 504.08 µg /g in the flour samples. Beta-carotene found in 2mm thickness OFSP flour samples was significantly (p<0.05) higher than the level from 4 mm thickness flour samples. Indirect Solar drying method promoted β -carotene retention, having values of 504.08 µg/g (2mm thickness) and 432.85 µg/g (4 mm thickness) in flour samples, while lowest β -carotene content was found in OFSP flour samples dried with open drying method for the 2 mm thickness (115.72 µg/g) and 4 mm thickness (104.48 µg/g), respectively. Similarly, rehydration ratio was significantly (p<0.05) higher in 2 mm thickness of OFSP (2.76-3.91) flour samples than in 4 mm (2.22-2.87) OFSP flour samples. Rehydration ratio was highest in 2mm (3.91) and 4 mm (2.87) samples of freeze drying method. Slice thickness positively affected the beta carotene retention and rehydration ratio on OFSP flour more than drying methods. Therefore, 2 mm slice thickness and indirect solar drying methods are recommended for processing of high quality β -carotene OFSP flour.

Drying, β-Carotene, OFSP, Thickness, Flour, Rehydration Ratio.

Drying is one of the most widely used methods for preserving agricultural products. The main purpose of drying agricultural products is to reduce their water content so as to minimize microbial and other sources of spoilage during storage. Drying is important because, quality deterioration during storage virtually depends on the level of moisture in products since moisture content reduction reduces degradation and chemical enzymatic reactions Sweet potato is cultivated throughout the tropics and warm temperate regions of the world for its starchy roots as a source of energy and other nutrients Beta-carotene (Provitamin A) is a member of a family of molecules known as the carotenoids, which are made up of a basic isoprene structure (Innocent et al., 2011). The concentration of β-carotene in orange-fleshed sweet potato (OFSP) variety was responsible for the orange flesh colour hence, it has been recognized as a readily available vitamin A source Orange-fleshed sweet potatoes contain carotenoids in different amounts Appropriate drying method is needed for β-carotene (nutrient) retention Though, OFSP is gaining importance as a cheap source of antioxidant (high in beta carotene) to combat Vitamin A Deficiency (VAD), however, its high moisture content and high nutrients, makes its highly perishable and hardly store for long after harvest Flours obtained from the dried slices could be used as whole flour or for formulation of composite flours for preparation of confectioneries (Doymaz, 2012).Pure making for OFSP intermediate product has been in use, dried form (flour) require less facility to process and stored. Hence, processing OFSP to flour by adequate drying methods may translate to its increased utilization (Fresco & Baudoin, 2004).

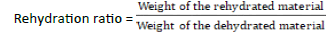

Rehydration of dried material may be described as a measure or index quality of the injury to the material, which occurs because of drying and treatment that precedes dehydration The extent of rehydration depends on the degree of structural and cellular disruption Rehydration ratio is important, in that, its serves as major information on how to reconstitute dried material, for optimal utilization (Sebben et al., 2012). Therefore, the present study was designed to determine the effect of processing (different drying methods and slice thickness) on the β-Carotene retention and rehydration ratio in OFSP flour samples. Application of the study may be used by OFSP flour processors for appropriate drying method(s), that could preserve beta carotene and to provide information on optimal reconstitution quality of dried OFSP flour (Fana Haile & Fisseha, 2015).

Materials

Fresh OFSP purchased from Wool worth’s Super market, Hath field Pretoria, South Africa was used for this experiment.

Facility/Equipment

Fresh Orange-Fleshed Sweet Potato samples were processed with the equipment in the department of Food Science, University of Pretoria, Hat Field, South Africa.

Sample Preparation/Drying

The following unit operations: Sorting for uniform sizes, washing under clean running tap water to remove sand and other extraneous material and then air dried away from direct light. The fresh procured OFSP samples were diced into 2 mm and 4 mm using semi-automated slicer (Lee et al., 2013). Each slice thickness was further sorted for uniformity, divided into five portions and dried under five drying methods at approximate durations: oven (60°C 24 hours); open sun 3 days; freeze 12 hours, indirect solar approximately 2 days and 2 days direct solar.

Well dried chips were milled (MF 10. IKA WERKE 3000-6500 1/Min. and sieved (500μm) to obtained uniform particle size flour, vacuum packed and stored under -20°C freezer for further analysis to prevent oxidation reaction (Innocent et al., 2011).

Determination of β-carotene Content

The following protocol was used in the extraction of the fresh OFSP roots and each of the dried samples: Two (2 g) of each sample was weighed into 50 ml beaker, 20 ml Tetra Hydro Furan (THF) was added, stirred on magnetic stirrer for 30 miniutes under dark environment and the upper clear layer was carefully filtered to rotary evaporator flask covered with aluminium foil and the residue was reextracted until it became colourless The filtrate was then evaporated to dryness at 40°C on rotary evaporator (IKA HB 10, IKA RV8 SO99, and Germany) to separate the extraction solvent from the sample. Then, 1 ml Toluene was used to dissolve the dried residue and 4 ml HPLC mobile phase (Acetonitrile-58%, methanol-35% and THF-7%) was used to quantitatively rinsed the solution into 10ml test tube, well labelled and wrapped in aluminium foil and kept in -20oC condition (Krokida & Marolis, 2001) The β-carotene content of the dried OFSP samples were evaluated by following the procedures of using a prominence Ultra- Fast Liquid Chromatography (UFLC),SHIMADU Tokyo, Japan, equipped with a SIL 20A Prominence auto sampler, DGU-20A Prominence degasser, a CTO-10 as VP Shimadzu column oven and a SPD-M 20A Prominence diode array detector. The β-carotene production was quantified using a standard calibration curve which was obtained by authentic β-carotene from Sigma Chemical Co. (Cat. no. 7235407) from the slope of five concentrations (10 pp to 200 ppm). About 3 ml of each dried sample extract was filtered (0.45μm) into Eppendorf tube (Xiao et al., 2019). The filtrate was then transferred to the insert vial already packed in the 2 ml brown vial before injecting. The 20 μl of the extract was injected to the UFLC. Separations were carried out on the Waters Nova Pak-C18 4 μm 3.9 × 300mm Column, serial No: 11913700613812, Part number: WAT011695. The flow rate was 1 ml/min. The chromatograms (peaks width, retention time and resolution) were calculated using Microsoft excel 2016.

The dried chips obtained from the five drying methods and two different thicknesses differs in intensity as shown in Figure 1.

Determination of Rehydration Ratio

Rehydration ratios of the different dried slices were determined using the method described by Ranganna (1986). Five (5 g) each of dried sweet potato slices (2 mm and 4 mm) were rehydrated in water at 95°C (± 1°C) and maintained for 10 min. Then, the samples were drained, and reweighed. The rehydration ratio (RR) was calculated as follows:

Statistical Analysis

The experiments were performed with two replicates for each five drying methods and two thicknesses. Descriptive statistics were performed for all variables by XLSTAT (2014) and SPSS Version 20. Two factorial analysis of variance (ANOVA) was performed to test the differences among the drying methods and two thicknesses for rehydration ratio and β-carotenoid contents by ultra-fast high-performance liquid chromatography. The 5% level of least significance was used to determine any differences in the mean values between different drying methods and two thicknesses (Nicanuru et al., 2015).

The beta carotene contents of the experimental OFSP are presented in Table 1. There was variance in percentage of carotene retention.

| DRYING METHOD | BETA CAROTENE (µg/g)DW | |

|---|---|---|

| 2mm | 4mm | |

| Oven Dry | 246.78 ± 0.05g | 233.54 ± 0.41 h |

| Open Sun Dry | 115.72 ± 0.56i | 104.48 ± 0.66 j |

| Freeze Dry | 423.49 ± 0.96c | 337.58 ± 1.39 f |

| Direct Solar Dry | 379.21 ± 0.00 d | 371.80 ± 1.02 e |

| Indirect Solar Dry | 504.08 ± 0.78a | 432.85 ± 0.51 b |

Table 1. Beta carotene of OFSP flour as influenced by drying method and slice thickness.

Key: OD = Oven drying, OS = open sun drying, FD = freeze drying, DS = direct solar drying, and ID = indirect solar drying (Figure 2).

Key: -Values are means ± standard deviation of duplicate runs of beta carotene Means in vertical with different superscripts are significantly (p<0.05) different among the drying methods and thicknesses. While, FR* = fresh sample, OD = Oven drying, OS = open sun drying, FD = freeze drying, DS = direct solar drying, and ID = indirect solar drying.

The intensity of the orange colour in OFSP reflects the concentration of beta-carotene present in the sweet potato (Ogunka, 2021). In this study the same variety was used. The beta carotene contents on dry weight ranged from 115.32 ± 0.56 to 504.62 ± 0.78 μg/g for 2 mm slice thickness. While 4 mm slice thickness had a range of 104.48 ± 0.66 to 432.85 ± 0.5 μg/g, for open sun drying and indirect solar drying respectively in all cases. There was general decrease in the beta carotene contents in the flours compared to the fresh value (942.731 ± 0.04 μg/g). Thickness 2 mm had significant (p<0.05) higher amount of beta carotene than values observed in 4mm thickness across the five drying methods (oven, open sun, freeze, direct solar and indirect solar dryings) (Woolfe, 1992). This may be caused by the exposure of samples to oxygen or/and heat for a longer period during drying for thicker slices (4 mm) than the 2mm thick slices. Also, exposure of the samples, in each unit operation could be responsible for the general reduction. Indirect solar drying had highest beta carotene values of 504.62 ± 0.78 μg/g followed by freeze drying 423.40 ± 0.96 μg/g, direct solar drying 379.29±0.00 μg/g, conversely, direct solar drying had higher significant (p<0.05) value 371.67 ± 1.02 μg/g than freeze drying 337.58 ± 1.39 μg/g in 4 mm thickness samples, followed by open drying 246.77 ± 0.05and 233.53 ± 0.41 μg/g. The other drying method (open sun drying) had significantly (p<0.05) lowest amount (115.32 ± 0.56 and 104.48 ± 0.66 μg/g of beta carotene contents among all the drying methods. The colour of each dried OFSP was physically observed (Nzamwita et al., 2017). The values ranged between 2.76 ± 0.15 and 3.91 ± 0.02 for direct solar drying and freeze drying respectively in 2mm while 4 mm thickness showed a range of 2.22 ± 0.05 (open sun drying) to 2.87 ± 0.01 (free ze drying).

The results of the interaction among thickness and drying methods are presented in Tables 2a & 2b.There was positive interaction among the drying methods and thickness. Thickness had more effects on beta carotene retention and rehydration ratio than method of drying (Noomhorm, 2008).

| Source | DF | Sum of squares | Mean squares | F | Pr> F |

|---|---|---|---|---|---|

| Drying | 4 | 317024.6419 | 79256.1605 | 138547.3063 | < 0.0001 |

| Thickness | 1 | 7172.9113 | 7172.9113 | 12538.9312 | < 0.0001 |

| Drying*Thickness | 4 | 5709.7859 | 1427.4465 | 2495.3122 | < 0.0001 |

Table 2a.Type I Sum of Squares Analysis Variables for Beta Carotene.

| Source | DF | Sum of squares | Mean squares | F | Pr> F |

|---|---|---|---|---|---|

| Drying | 4 | 1.5943 | 0.3986 | 26.4106 | < 0.0001 |

| Thickness | 1 | 2.0693 | 2.0693 | 137.1146 | < 0.0001 |

| Drying*Thickness | 4 | 0.4013 | 0.1003 | 6.6478 | 0.0071 |

Table 2b. Variable for Rehydration Ratio.

Results of the rehydration ratio were significantly different (p<0.05) among the different drying methods and slice thickness as shown in Figure 3.

Key: OD = Oven drying, OS = open sun drying, FD = freeze drying, DS = direct solar drying, and ID = indirect solar drying.

Although, degradation of β-carotene content occurred in all the drying methods but what was left in the flour was still substantial. However, the good β-carotene content retention obtained in flour from indirect solar drying methods was more. It could therefore be concluded that indirect solar drying method may be more appropriate for OFSP flour processing. Hence, for high β-carotene content retention in OFSP flour indirect solar drying is recommended.

Ben-Amotz A, & Levy, Y (1996). Bioavailability of a natural isomer mixture compared to synthetic all-trans β-carotene in human serum. Am J Clin Nutr. 63: 729-734.

Indexed at, Google Scholar, Cross Ref

Doymaz İ (2012). Infrared drying of sweet potato (Ipomoea batatas L.) slices. J Food Sci & Technol. 49: 760-766.

Indexed at, Google Scholar, Cross Ref

Fana Haile SA, & Fisseha A (2015). Effects of pre-treatments and drying methods on chemical composition, microbial and sensory quality of orange-fleshed sweet potato flour and porridge. Am J Food Sci Technol. 3: 82-88.

Indexed at, Google Scholar, Cross Ref

Fresco LO, & Baudoin WO. (2004). security. Food security and vegetables: a global perspective. 7- 42.

Indexed at, Google Scholar, Cross Ref

Inocent G, Adelaide DM, Gisele EL, Solange MOR, Richard EA, Elie F (2011). Impact of three cooking methods (steaming, roasting on charcoal and frying) on the beta-carotene and vitamin C contents of plantain and sweet potato. Am J Food Technol. 6: 994-1001.

Indexed at, Google Scholar, Cross Ref

Krokida & Marolis (2001). Structural properties of dehydrated products during rehydration. Int J Food Sci Technol. 36: 529–538.

Indexed at, Google Scholar, Cross Ref

Lee KH, Wu TY, & Siow LF (2013). Spray drying of red (Hylocereus polyrhizus) and white (Hylocereus updates) dragon fruit juices: Physicochemical and antioxidant properties of the powder. Int J Food Sci Technol. 48: 2391-2399.

Indexed at, Google Scholar, Cross Ref

Nicanuru C, Laswai HS, & Sila DN (2015). Effect of sun-drying on nutrient content of orange fleshed sweet potato tubers in Tanzania. Sky J Food Sci. 4: 91-101.

Indexed at, Google Scholar, Cross Ref

Noomhorm A (2008). Overview of dehydration method on quality of fruit and vegetables. SWU Sci J. 23: 9-22.

Indexed at, Google Scholar, Cross Ref

Nzamwita M, Duodu KG, & Minnaar A (2017). Stability of β-carotene during baking of orange-fleshed sweet potato-wheat composite bread and estimated contribution to vitamin A requirements. Food Chem. 228: 85-90.

Indexed at, Google Scholar, Cross Ref

Ogunka NP, Ezeama, CF & Ukpabi, UJ (2021). Physicochemical and microbial properties of orange-fleshed sweet potato flour produced with sun-drying and sulphating agent. Food Res Int. 5: 315-320.

Indexed at, Google Scholar, Cross Ref

Sebben JA, Trierweiler LF, & Trierweiler, JO (2017). Orange‐fleshed sweet potato flour obtained by drying in microwave and hot air. J Food Process Preserv. 41: e12744.

Indexed at, Google Scholar, Cross Ref

Woolfe JA (1992). Sweet potato: An untapped food resource. Cambridge, Cambridge University Press, 643.

Indexed at, Google Scholar, Cross Ref

Xiao HW, Lin H, Yao XD, Du Z L, Lou Z, & Gao ZJ (2009). Effects of different pretreatments on drying kinetics and quality of sweet potato bars undergoing air impingement drying. Int J Food Eng. 5: 19

Indexed at, Google Scholar, Cross Ref

Citation: Omodamiro R.M et al., (2022).Drying methods and slice thickness of orange-fleshed sweet potato flour and beta carotene content retension.AJFST.13:011.