Research Article - International Research Journal of Biotechnology ( 2025) Volume 16, Issue 1

Received: 17-Jun-2024, Manuscript No. irjob-24-139284; Editor assigned: 20-Jun-2024, Pre QC No. irjob-24-139284 (PQ); Reviewed: 04-Jul-2024, QC No. irjob-24-139284; Revised: 08-Jan-2025, Manuscript No. irjob-24-139284 (R); Published: 15-Jan-2025, DOI: 10.14303/2141-5153.2025.99

The selection of working fluid, operating conditions, system configuration and design are the major factor that influence the performance, cost estimation and environmental impact of heat pump drying system. The aim of this research was to investigate, the performance and economic value of vapour compression heat pump for heating process and drying of tomatoes slices at drying air temperatures 40°C, air flowrate of 1 km/hr and at evaporating temperature and condensing temperature of 10°C and 15°C respectively using diethyl-ether as working fluid at 700 kpa discharge pressure of compressor and 120 kpa valve pressure. The specific moisture extraction ratio is 0.4013 kg/KWh, specific energy consumption is 2.49 kWhr/kg. energetic coefficient of performance of HPD system is 5.83, exergetic coefficient of performance of HPD system is 30.20% and overall exergy efficiency at the highest ambient air temperature (30°C) is 33.30%. The exergy analysis of the compartments of the heat pump drying system were obtained. Condenser and evaporator of the system have the major contribution in exergy destruction with low exergy efficiency. Payback period is 1.86 years and present net worth is 4,122,210 USD.

Coefficient of performance, Exergy efficiency, Specific moisture extraction rate, Specific energy consumption, Working fluid

Due to its commercial importance, tomato is one of the most scientifically studied vegetables. It is highly perishable, with post-harvest losses ranging from 25 to 50% (Antonijevi D et al., 2011).

Drying is simultaneous heat and mass transfer process through which moisture is removed or reduced from a material. The basic objective of drying is to remove water from the material so as to and the consequent limitation of microbial activity, longer shelf-life and significant reducing of the volume of finish products (Bingjie M et al., 2015).

The rapid rise in energy costs, supply security concerns, pollutant emissions, and global climate change have all rendered heating systems unsustainable in their existing forms, both now and in the future (Chian Wen C et al.,2011). To tackle these issues, alternative heating solutions that focus on reducing energy consumption and improving heating performance while reducing negative impacts or negative influence on the environment must be investigated (Correia AF et al., 2015). Heat pumps have long been recognized as an effective means of drying and energy recovery (CoÃÂ??kun S et al., 2017). During the operation, a heat pump will be used to dry the difference between the hot heat produced by the condenser and the cold heat produced by the evaporator (Fayose F et al., 2016). The hot heat produced by the condenser will be supply heat require for drying of the material (Hany S et al., 2013).

Heat pumps have long been recognized as an effective means of drying and energy recovery (Jimenez T, 2015). Due to the economic benefits resulting from high Coefficient of Performance (COP) values, mechanical heatpump systems become convenient devices for heating and cooling purposes though with low primary energy efficiency (Kivevele T et al., 2014).

In this present study, the performance and economic value of vapour compression heat pump for heating process and drying of tomatoes slices was evaluated through energy analysis, exergy analysis, drying analysis and economic analysis using ASPEN PLUS simulation model (Figure 1).

Compression heat pump drying system

Figure 1. Schematic diagram of compression heat pump drying system.

The HPD system consists mainly of two subsystems: A compression heat pump and a drying chamber (Ursula K et al., 2015). Through the evaporator, the heat pump extracts and transfers heat from natural heat sources in the environment, industrial or residential waste, a chemical reaction, or dryer exhaust air (Sannan S et al., 2020). The compressor increases the working fluid's pressure, which increases the condensing temperature. In the condenser, the working fluid condenses, supplying high-temperature heat for drying process (Soni J et al., 2012). The heat pump drying system is made up of a heat pump (which includes a compressor, condenser, expansion valve, and evaporator), a dryer, and air cycling circuits that connect the heat pump and dryer (Figure 1). The Closed HPD (as illustrated in Figure 1) operates on the principle that the dryer's exhaust air enters the evaporator of heat pump, where it is cooled and the moisture in the air is condensed and removed. The cool and dry air from the evaporator then goes into the condenser of the heat pump and is heated. The hot and dry air then enters the dryer and absorbs the moisture in tomato slices placed in the drying chamber and becomes exhausted air at the outlet of the dryer, and the cycle repeats. Because the heat pump retrieves the heat in the exhausted air to heat the air entering the dryer while it removes the moisture in the exhausted air, it achieves a high energy efficiency in the drying of biological materials such as tomato slices which are thermally and oxygen sensitive.

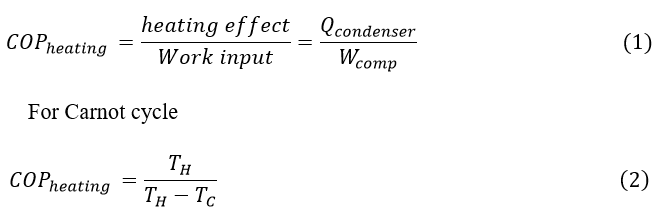

Coefficient of performance for heating COPheating is given as:

Exergy analysis and drying analysis of vapour compression heat pump drying system (Table 1).

The total exergy destruction is calculated using:

Exdest, total= Exdest, comp + Exdest, cond + Exdest, evap + Exdest, valve + Exdest, dryer (5)

| Compartments | Exergy Loss | Exergy loss coefficient | Exergy efficiency |

| condenser |

|

|

|

| evaporator |

|

|

|

| compressor |

|

|

|

| Valve |

|

|

|

| dryer |

|

|

|

Table 1. Calculation of exergy parameters of the compartments.

The exergy efficiency of the heat pump drying system is evaluated as:

Economic analysis

Different economic indicators would be used for economic analysis of heat pump drying systems under this study. The following parameters are to be considered to carry out cost economics;

The Payback Period (PP) of the heat pump drying system is given as The payback method measures the time period between investment and its recovery

The payback method measures the time period between investment and its recovery

The Present Worth (PW) is given as

Net Present Worth=Present worth-Initial investment (11)

Total capital cost=Initial investment cost+operating cost (12)

t is the life span of dryer (year), P is daily benefits received from the drying system (USD/day) n is total working days in a year (day) d is discount rate.

The tomato slices at room temperature are assumed to be a solid mixture of the components in Table 3. The physicochemical properties of the tomato were created in ASPEN PLUS environment. The drying air temperature is assumed to be 40°C. The initial and critical moisture content are assumed to be 0.1 and 0.01 respectively. Thickness and radius of tomato slices are assumed to be 2 mm and 2 cm respectively. The number of tomato slices dried per turn (N) is assumed to be 12,000 slices. Dimension of the dryer is assumed to be 61 cm × 61 cm × 61 cm (with a modified drying chamber). The flowrate of tomato slices and air are assumed to be 400 kg/h. and 200 kg/h. Flowrate of the working fluid is 1 kmol/h. and isentropic efficiency of compressor is 85%. The exergy reference temperature and pressure were assumed to be 30°C and 1 atm respectively.

Properties of tomato components

The main components of tomato are their percentage composition are shown in the Table 2.

| Components | Percentage of composition |

| Protein | (%) 2.01 |

| Ascorbic acid | (%) 2.50 |

| Ascorbic acid | (mg/100) 19.33 |

| Phenolic compound | (mg/100) 30.5 |

| Carotene | (mg/100) 13.56 |

| Lycopene | (mg/100) 0.51 |

| Moisture(water) | (%) 94.60 |

Table 2. Main components of tomatoes.

Using diethyl-ether as working fluid at 700 kpa discharge pressure of compressor and 120 kpa valve pressure. Energy, exergy and drying analysis were done using eqn (1) to eqn (12). The summary of the results is given in Table 3 below.

Discussion: The energetic coefficient of performance of the system is 5.83 that is, energy obtained from the system is 5.83 times the energy used by the system. In addition to the energy analysis, a full exergy analysis was done to identify the components where inefficiencies occur and how to correct it. The exergetic coefficient of performance and overall exergy efficiency of the system are 30.2% and 33.3% respectively. The exergy loss coefficient of the condenser is the largest in the system, accounting for 42.65%, then exergy loss coefficient of the evaporator, the compressor, the valve, and the dryer account for 14.3%, 8.6%, 0.86% and 0.23% respectively. The exergy destruction (exergy loss) in the components of the system are as result of pressure drop arising from phase change (especially in compressor and valve), the temperature difference between working fluid and heated environment, heat transfer and heat losses due to friction (especially in condenser and evaporator).

Condenser and evaporator have the major contribution in exergy destruction. The high exergy losses of heat transfer in condenser (64%) and evaporator (21.5%) result in low overall exergy efficiency of the system. The key components to improve the overall exergy efficiency of the system are evaporator and condenser. Hence more attention should be given while designing these components for less total exergy destruction. The condenser has the highest exergy loss, accounting for 64% of the total exergy loss of the system. The exergy loss in the condenser can be reduced by adopting condenser type of higher coefficient of heat transfer or by removing any scale and heat resistance pipe. To reduce exergy losses in evaporator and condenser, enlargement of the surface area and the use of a very good conductive material with high coefficient of heat transfer is a good recommendation. This problem can also be solved by reducing the temperature difference of heat-transfer, which can be done by adopting the screwed pipe with great heat transfer coefficient, or removing the scale and heat resistance in pipe. When the pressure of the compressor is high, double stage compressor can be adopted which reduces the inlet temperature and exergy loss.

For the drying analysis, the specific moisture extraction rate and specific energy consumption are 0.4013 kg/KWhr and 2.49 kWh/kg respectively. These values show the system has good drying efficiency and also reveal the profitability and commercialization of the drying system.

| S/N | Parameters | Ether |

| 1 | Specific moisture extraction rate (Kg/KWh) | 0.4013 |

| 2 | Specific energy consumption (KWh/Kg) | 2.49 |

| 3 | Compression ratio | 5.83 |

| 4 | COPenergetic | 5.83 |

| 5 | COPexergetic (%) | 30.2 |

| 6 | Exergy efficiency of condenser (%) | 36.2 |

| 7 | Exergy efficiency of evaporator (%) | 46.7 |

| 8 | Exergy efficiency of compressor (%) | 86.3 |

| 9 | Exergy efficiency of dryer (%) | 99 |

| 10 | Exergy efficiency of valve (%) | 49.7 |

| 11 | Overall exergy efficiency of the system (%) | 33.3 |

Table 3. Results of energy analysis, exergy analysis and drying analysis.

Economic analysis of vapour compression heat pump drying system

Total benefit received per year=Amount of tomato dried × Cost of 1 kg of dried tomato × Total working time in a year × Life span

Total capital cost=Initial investment cost+operating cost

Initial investment cost=Total capital cost-operating cost

Initial investment cost=2,325,510 USD-1,309,570 USD=1015940 USD

The simple payback period is calculated by dividing the initial investment by the annual cash flows (Table 4). The formula is

The Present Worth (PW) is given as

Net Present Worth=Present worth-Initial investment

NPW=4,668,306 USD-546096 USD=4,122,210 USD

| Total capital cost (USD) | Total Operating Cost (USD/year) | Equipment Cost (USD) | Total benefit received per year (USD/year | Desired Rate of Return/year | Payback Period (Year) | Net Present worth (USD) |

| 2,325,510 | 1,309,570 | 470,720 | 546,096 | 20 | 1.86 | 4,122,210 |

Table 4. Results obtained from simulation for economic analysis of the heat pump drying system.

The selection of working fluid, operating conditions and system configuration and design are the major factor that influence the performance and economic value of heat pump drying system. The specific moisture extraction ratio is 0.4013 kg/KWh, specific energy consumption is 2.49 kWh/kg. energetic coefficient of performance of HPD system is 5.83, exergetic coefficient of performance of HPD system is 30.20% and overall exergy efficiency at the highest ambient air temperature (30°C) is 33.30%. Payback period is 1.86 years and present net worth is 4,122,210 USD. The drying heat pump system can be optimized for better performance.

[Crossref]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref]